Article 2 of 2

Let's continue the discussion on new fibres & fabrics. In Article 1, I talked about Super Absorbent Fibre and Kapok Fibre. Few interesting fibres to know about are given below :

Nettle Fibre :

Nettle Fibre :

Is a sustainable fibre that has traces of usage in apparel since the past 2000 years. Nettle is a bast fibre obtained from the stem of the wild-growing stinging nettle plant, found in temperate regions of the world. This fibre is being considered as the fabric of the future by many European fashion guru's. With the concerns over the environmental damage caused by cotton production, nettle has grasped the interest of many.

With advancements in technology and cross-breeding of nettle, its possible to get super high-fibre plants that are strong, flexible, versatile and have a good length for spinning. This can easily replace cotton, which enjoys a top position in the fibre market today.

Nettle fibres are hollow in nature with high fixed carbon, which provides natural air conditioning. It means they are filled with air inside which creates a natural insulation. Also, nettle is cool in summer and warm in winter. Nettle crop uses lesser water and pesticides to grow. It can be blended with cotton and other fibres to get more desirable properties and effects on the fabric.

The Center of Sustainable Fashion claims that the Himalayan nettle is stronger, finer, and more flexible than regular linen, indicating that eco-friendly clothing made from it will be more durable and of better quality.

Banana Fibre :

It is a natural fibre, which was traditionally used to make ropes, mats & composite materials. Today, it has entered into apparel applications due to increased environmental awareness & growing demands for eco-friendly fabrics. It is light and comfortable to wear, preferred by people as summer wear. Its widely used in home textiles.

History shows that people made banana fibres since early 13th century. Its interesting to note, that Japan’s Kimonos were made using Banana fibres 400 years ago.

Banana plants coarse outer layer is commonly used for home furnishings while the inner and silky layer is ideal for fine fabrics used in apparel.

Appearance of banana fibre is similar to that of bamboo fibre and ramie fibre, but its fineness and spinnability is better than the both. It is a strong fibre with less elongation, which has shiny appearance depending upon the extraction & spinning process. It is light weight and has strong moisture absorption quality. It releases moisture very fast.

Banana fibre is a more sustainable alternative to silk. Fabrics made from banana fibres are soft and supple. It is said to be nearly carbon neutral. Though it is not durable like hemp, bamboo, silk and cotton, still researches are working on this aspects.

Pineapple Fibre :

This is a sustainable fibre option, especially now, when the designers are catering to eco-conscious customers and looking to move from animal leather and synthetic fibres. Philippines pineapple silk fabrics are known for their use in hand embroidered over shirts and formal shirts.

Cheaper cotton had ceased the growth of pineapple fibres in the textile world in the past. But now sustainability requirements has brought it back into the apparel market.

The leaves of the pineapple plant are the major source of the silky pineapple fibre. Alternatively, fibres extracted from the waste of pineapple fruits are blended with polyester or silk to make organic fabrics with a silky texture.

Pineapple fibres have elegant appearance with natural shine similar to linen, light weight, blend with other fibres easily, softer than hemp, have better texture than silk and can be easily washed. Normally 100% pineapple fibre yarns are not manufactured, but are regularly blended with cotton, polyester and silk.

Coffee Ground Fibre :

This new fibre shows a greener future to the fashion industry, a fibre from trash. A new and advanced technology makes it possible to recycle ground coffee into wearable textile fibre. Coffee yarn is multi-functional; with uses extending to a variety of products like household items to sportswear & performance wear. Even inner wear, bedding and footwear were developed from these fibres.

This fibre has excellent natural properties like anti-odour, UV protection and fast drying. Coffee ground yarn and resulting fabric comprises of 5% up-cycled coffee grounds and 95% recycled polyester, making it eco-friendly.

Coffee fibre is turning a lot of eye balls with its unique sustainable features. Up- cycling & eco-friendly nature of this product is one of the key differentiators. Features of waste coffee grounds themselves are suitable for clothing. Also, material saving & energy efficient processes followed in manufacturing this fibre, will help take this fibre to new heights in apparel industry.

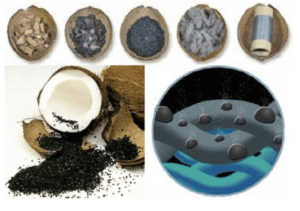

Coconut Shell Fibre :

Coconut Shell Fibre is made by carbonising the coconut shell. The coconut material has a fine vesicular structure, which is similar to charcoal fibre, but different in the fact that the structure is maintained after its made into a fibre. These carbonised particles are mixed with polyester or nylon polymers and filament/staple fibres are spun.

Because of this, the fibre has excellent antibacterial & disinfectant, quick drying and ultraviolet protection qualities. Quick drying function in this coconut shell fibre is twice compared to other variety of polyester fibres available in the market. Its disinfectant and UV rays blocking function is far better than regular polyesters.

Developments are going on in making regular t-shirts, sports performance apparel, socks, home furnishings etc. It is environment-friendly and is human-friendly, surely something our apparel industry needs to adopt & take forward.

Water Hyacinth Fibre :

The new organic apparel fibre; a free-floating perennial plant that can grow to a height of 3 feet which is abundantly available. It grows readily without any need for sowing, weeding or fertilising & does not require any land space.

It has a good tensile property but also has high C.V% value. Hence, it is not suitable for tensile related products but is used for disposable products. It has good water absorption, comparative to cotton.

Now a days water hyacinth plant is used for decorative purposes and it plays a big role in hand crafted products like hand bags, wallets, flower pots, fashion accessories, mats etc. Many creative and decorative home furnishing products are manufactured from water hyacinth stem. Pre-treated water hyacinth fibre shows absorbency of about 5 to 11 times higher than its weight. So, it can be used as an absorbency material of various end uses. Chemical treatments make the fibre fine and soft with required crimps suitable for knitting and weaving.

Blends of water hyacinth fibre with polyester staple yarns are available in the market. 15s Ne with 80/20 and 65/35 polyester / water hyacinth produces a good resultant apparel yarn. Count of less than 15s Ne are produced to make home textiles.

All the 8 fibres discussed in this 2 part article are not new, but have not been used extensively in the apparel industry. They are eco-friendly and sustainable which will surely make them the flag bearers of the new generation apparel revolution.

See you in my next article, follow me…

RELATED TOPICS:#Sourcing,Apparel,Fashion,Innovation,sustainable,knit,fashion industry,fibres,nettle fabrics,banana fibre,pineapple fibre,coconut shell fibre,new fibres,yarn technology,Fashion Innovation,Textile,Textile Innovation,Satheesh Kumar

Leave a comment

Our email address will not be published. Required fields are marked *

16 Comments

ObetemoAug 01, 2024 at 23:20 pm

Muscle relaxants cialis otc

Buy cialis online overnight shippingFeb 24, 2024 at 20:11 pm

It's going to be ending of mine day, except before ending I am reading this enormous piece of writing to improve my know-how.

Pankaj GargJul 26, 2020 at 10:10 am

Very informative Sir.. Thanks for sharing and looking forward for more of such articles.

S.veerichettyJul 25, 2020 at 08:49 am

Good article to awareness creation on natural fibre.. nice Satheesh sir..

Saravanan MJul 24, 2020 at 20:04 pm

Dear Mr Sathis sir very interesting sustainable fibre details very interesting I am one of the leading Buying office in tirupur i need all the new and different. Thank for Will give us your contact RegarRegards Sara

Muthu KumarJul 24, 2020 at 14:04 pm

Very nice Satheesh to see as many varieties of fibers available, hope in future these will be more Eco friendly and good for skin

GopalakrishnanJul 24, 2020 at 10:31 am

Satheesh, very good article and nicely written. congrats and waiting for the next article

Kamal GuptaJul 24, 2020 at 10:31 am

Dear Satheesh ,With so much talk of sustainability ,your blog is a very insightful and in depth coverage of the discussion. Thanks

Rajashankaran VJul 24, 2020 at 10:09 am

Hi Satheesh sir, Nice info about sustainable fibre, During my college time have done project on sisal plant fibre. This was much interesting page. We need to explore these in our regular Apparels

Ravi MarappaJul 24, 2020 at 09:34 am

Hi Satheesh, great to see a beautiful article covering all the sustainable natural fibres and their blends, which i think is the future. If these fibres can be produced in bulk and with right marketing these can reduce lot of pollution as they are all biodegradable in nature. Good care on with your articles, ?

MahanteshJul 22, 2020 at 18:33 pm

Mr. Satheesh, Good coverage on the different type of sustainable Fibres i love to read. The regular routine blends- cotton, linen and polyester is become staple. One should look at compact seasonal natural blend.

ParameshkumarJul 21, 2020 at 20:28 pm

Hi Satheesh sir,great info about sustainable fibre. We need to explore these in our regular Apparels & Dave earth too, thanks ??

Praveen Rao. AJul 21, 2020 at 19:42 pm

Very much covered all viable sustainable fibers. With all this looking forward future fashion. It's clear that cotton alone can't lead future business.

SenthilkumarJul 20, 2020 at 10:38 am

Good coverage on sustainable fibres...it will help product developers for better understanding on fibres. Good job Satheesh

Ajay RavuriJul 20, 2020 at 10:17 am

Hey Satheesh, Great. We are now aware of these fabrics in detail. Also help throw light on the usuage of these fibers and cost impact. Will these kind of fabrics will really boast product quality and sales? I hope you will enlighten these facts in next article . Stay posting .. good

Ramesh.gJul 16, 2020 at 14:27 pm

thanks satheesh for taking us through various fibers which has great & specialized characters in order to make these workable it should be easily available in the market for manufacturing. Now a days everyone is looking for new fibers. nice & very informative article.