Article 1 of 2

In this article, I want to shed light on some of the new developments in the world of fibres.

Due to the vastness of this topic, the blog is divided into 2. This is the first of the series…

This exploration usually starts in every factory when they receive the below appreciation mail from the buyer before a season is about to end.

On receipt of such e-mails, factory merchant and development teams heart beats rise slowly. What are the new fibres we haven’t still used in our products ? We have used & produced everything we know. Where to find it ? How to source it ? Will it be production feasible ?

A preliminary work analysis is done and the development teams meetings are organised to finalise the route map & budget. This sets the new action plan in place…

Worldwide fibre usage in Textile Industry :

Cotton & Polyester are the preferred fibres used across the textile industry, forming about 76% of the total.

Cotton & Polyester are the preferred fibres used across the textile industry, forming about 76% of the total.

We live in a world in which technology is advancing at such a high speed that it is often difficult to comprehend its impact on our lives. The textile industry has likewise kept pace and today’s technology can provide fibres that go well beyond the best that nature can offer.

Natural fibres such as cotton, bast fibres and wool are created by nature, (may not be for the purpose of textiles creation). Making changes of their properties are very difficult. But in man made fibres, the properties can be changed by variation in fibre spinning, drawing and heat setting conditions. Now-a-days every new development in either natural or man made fibres comes by slightly changing their properties.

In today’s context sustainable fibres have taken prominence in our industry. Let us look at a few fibres which are heard of in the market, but may be not have been explored much or not commercially available as of now. Nonetheless they are being improved upon in order to make it available to the end consumers.

Super Absorbent Fibres (SAF) :

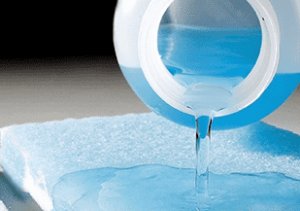

Acrylic based super absorbent fibre is a new generation fibre which has gained its prominence for its super absorption capacity. Super Absorbent Polymers (SAP) have the ability to absorb and retain large volumes of water and aqueous solution, this unique property makes them popular in the use in water absorbing applications. It is white in colour and possesses improved handling properties to be used in a wide range of fabrics. It provides extremely high rates of water and saline uptake. Because of its extreme water absorption capacity, it is widely used in diapers and filter products.

It can absorb up to liquid 500 times its weight. Super absorbent polymers are cross-linked so that they are insoluble in the liquid which they absorb. This is primarily done because the liquid absorbed should be retained strongly and exertion of pressure should not cause the liquid to move out. Super absorbent polymers were earlier made by grafting polyelectrolyte’s onto starch or cellulose which had good absorption capacity. But now they are made of sodium polyacrylate or partially neutralised acrylic acid. Depending upon the precise structure of polymer network and cross link density, the swelling and elasticity properties change from polymer to polymer.

It is used in Sports Textiles which need breathability, it is nothing but thermoregulation in clothes for sweat management by body perspiration and evaporation.

Kapok Fibre :

Kapok, a natural cellulose fibre found in the dried fruit of the kapok tree. Kapok is the most sustainable fibre in the market today, leaving no human footprint behind. It has very good properties like anti–moth, anti–mite and insulation properties comparable to down apart from silky soft and dry to touch.

Kapok, a natural cellulose fibre found in the dried fruit of the kapok tree. Kapok is the most sustainable fibre in the market today, leaving no human footprint behind. It has very good properties like anti–moth, anti–mite and insulation properties comparable to down apart from silky soft and dry to touch.

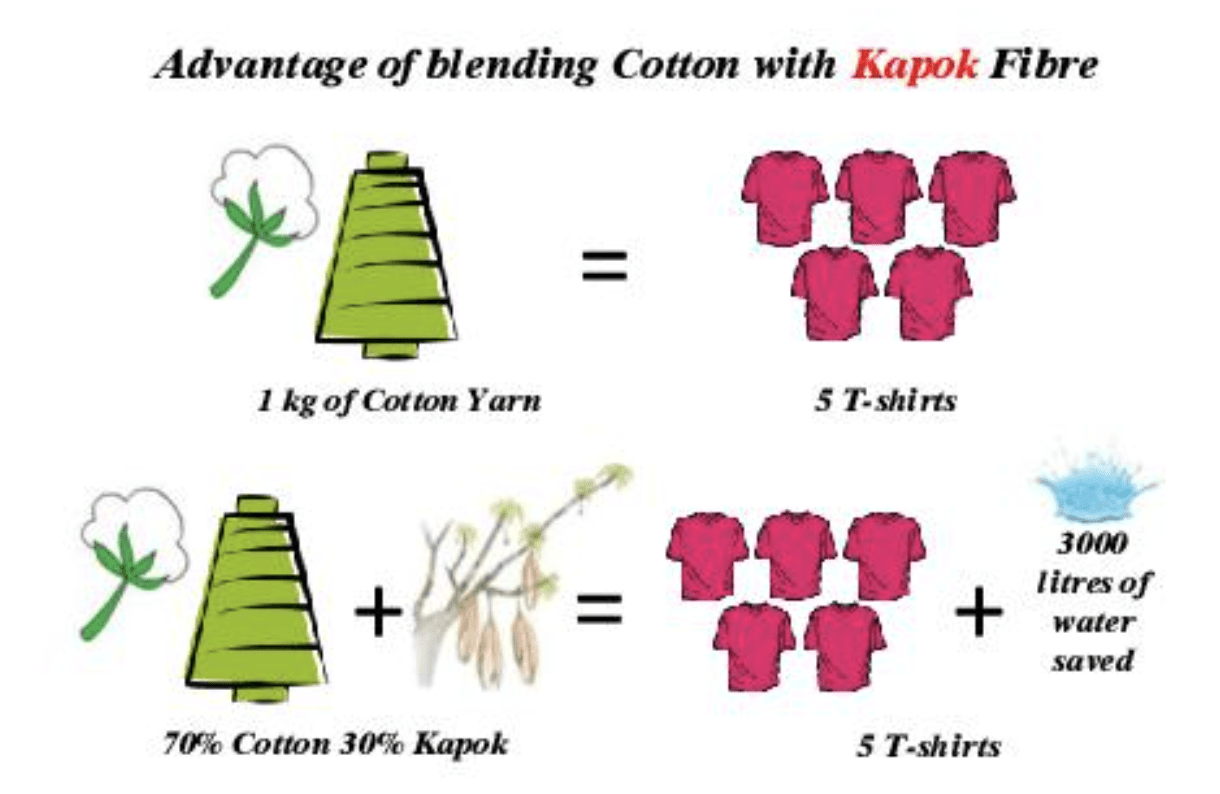

100% Kapok fibre cannot be converted directly to make a yarn to use in textiles and apparels as its spinnability is very low. However, blending it with other materials like cotton can save tremendous amounts of water. For example, if 1 kilogram of cotton, which is needed to make four t-shirts, is blended with just 30% of kapok, saves about 3,000 litres of water.

Kapok has been used widely for fillings, as it is one of the lightest hollow fibre. The technology has improved and kapok fibres have been used in fabric blends that can be spun, making the resulting fabrics softer and more comfortable to wear.

Let us read the continuation of these NEW FIBRES – WHO IS LOOKING FOR IT & WHEN – PART 2 …

See you in my next article, follow me…

RELATED TOPICS:#Textiles,Apparel,Fabrics,technology,Innovation,fibre,fabric,new,newfibres,kapok,SPA,Yarn Properties,Satheesh Kumar

Leave a comment

Our email address will not be published. Required fields are marked *

7 Comments

1850Jan 23, 2023 at 06:14 am

1850

GopalakrishnanJul 24, 2020 at 10:39 am

good satheesh

Steephen AnthonyJul 16, 2020 at 16:14 pm

Very good stuff & helps to enrich the knowledge of apparel enthusiasts. Thanks for the blog

Praveen Rao. AJul 13, 2020 at 18:50 pm

Very informative sir, looking for the Part 2 with lot more information and new.

SenthilkumarJul 13, 2020 at 06:53 am

All the best Sathish sir... Article is informative. I request you to cover the techno-economics of branded fibres also.

BhaskaranJul 09, 2020 at 12:51 pm

Sathish... good article..continue to touch all sustainable fabrics. also, on sustainable fabrics try to explain the document support required to state those are sustainable.

Ramesh.gJun 30, 2020 at 18:32 pm

Nice & Very informative article Satheesh, really look forward to know more with your part 2. Able to come across new things with your articles. Keep sharing..