THE FUTURE SERIES

Article 5 of 6

The Future of Fashion Sourcing

This is the penultimate post in this series of 6 blog posts that explore the changing face of the fashion industry. In this article I will discuss how the sourcing function needs to undergo a change to keep fashion companies abreast of their new realities.

For the purpose of this article the term ‘sourcing’ refers to the procurement, manufacturing & quality functions in the Fashion industry.

In this blog, I will discuss how the sourcing function needs to

- redefine objectives and sourcing structures,

- relook at how we define costs,

- move to a ‘consulting’ from ‘policing’ way of working and

- go digital and all that it entails to ensure that fashion companies are ahead of the curve.

Let’s start the discussion with understanding the purpose of having a sourcing function.

Is the function relevant any more?

REDEFINE OBJECTIVES AND SOURCING STRUCTURES

Let us start with a little bit of history. The word merchandiser or merchant comes from the traders in the 1800’s who would come in their ships and display their wares to the buyers. And from there was also born this function called sourcing. Retailers would come to traders wanting them to ‘source’ specific merchandise for their customers and stores.

In the golden age of fashion brands (’80’s through to the early 2000’s), sourcing took on the role of ensuring lowest possible cost for products delivered on time and within defined quality parameters.

And this has been the legacy ‘L1’ (lowest cost) sourcing.

As per capita incomes rose in manufacturing countries, sourcing organisations shifted to procuring from cheaper and cheaper locations like China, then Bangladesh and now African countries. Unlike other industries, apparel retail prices have been very stable over the last few decades, in fact even coming down in many cases.

But is L1 a relevant objective in todays brave new world? A classic example would be Zara who is a value retailer but with high cost procurement strategy; a sizeable amount of their production happens in Europe to enable faster speed to market.

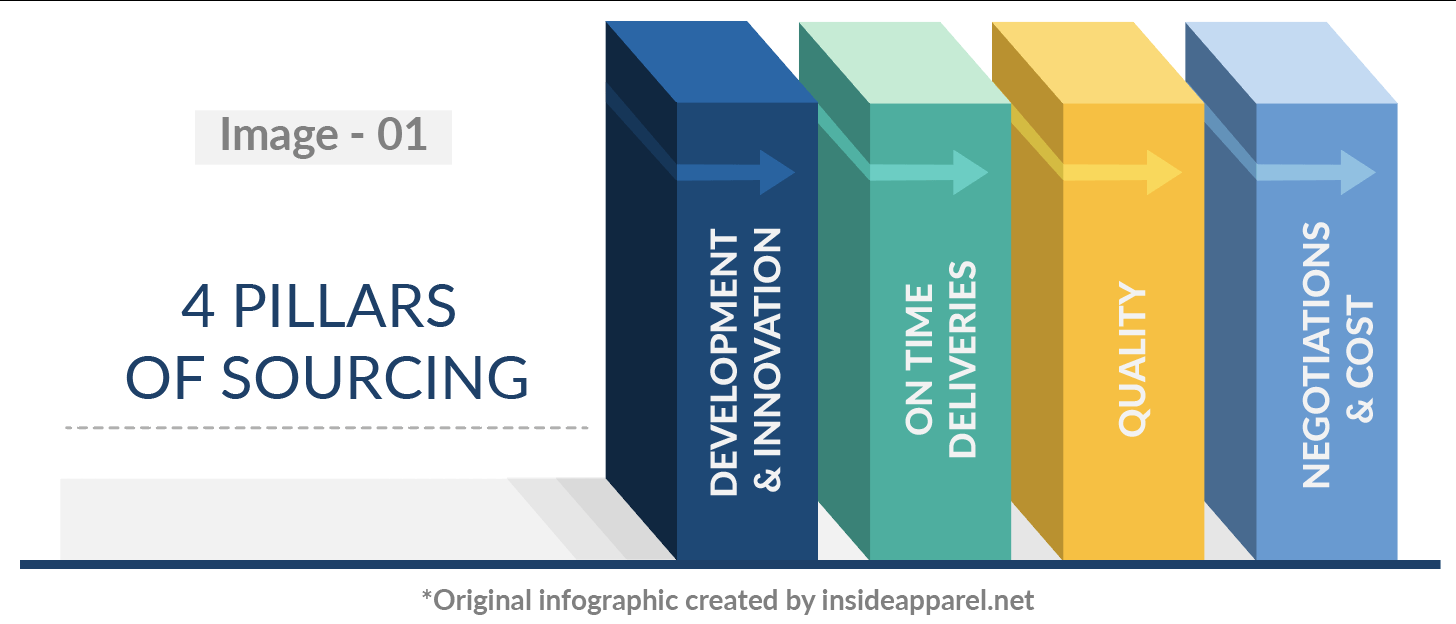

Let’s look at Image - 01 to understand the four pillars of the sourcing function.

Fashion companies need to structure their sourcing teams and clearly define their KPI’s based on their own business models, which we discussed in our previous article here. Now the importance of each of these four pillars and hence the way teams are structured will change to adapt to the brand positioning.

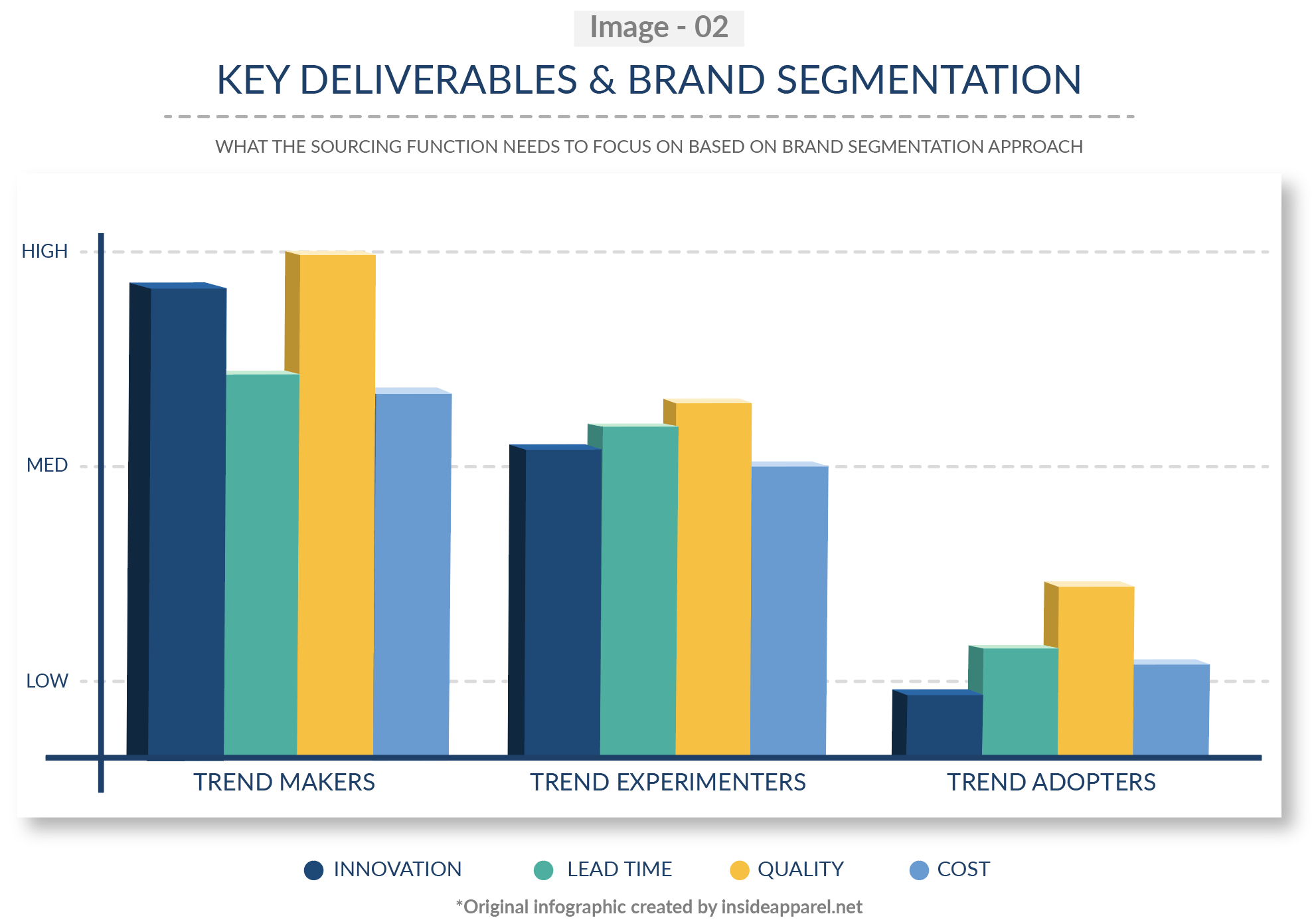

The above Image - 02 is indicative and will differ case to case, but the working, key deliverables and structure of sourcing teams will depend on these varied requirements. All companies need these structures, but in varying degrees and that will determine the no. of people in each department, their strength and the processes they follow.

This now brings us to another key aspect of the business - how do we define cost itself?

REDEFINE HOW WE MEASURE COST

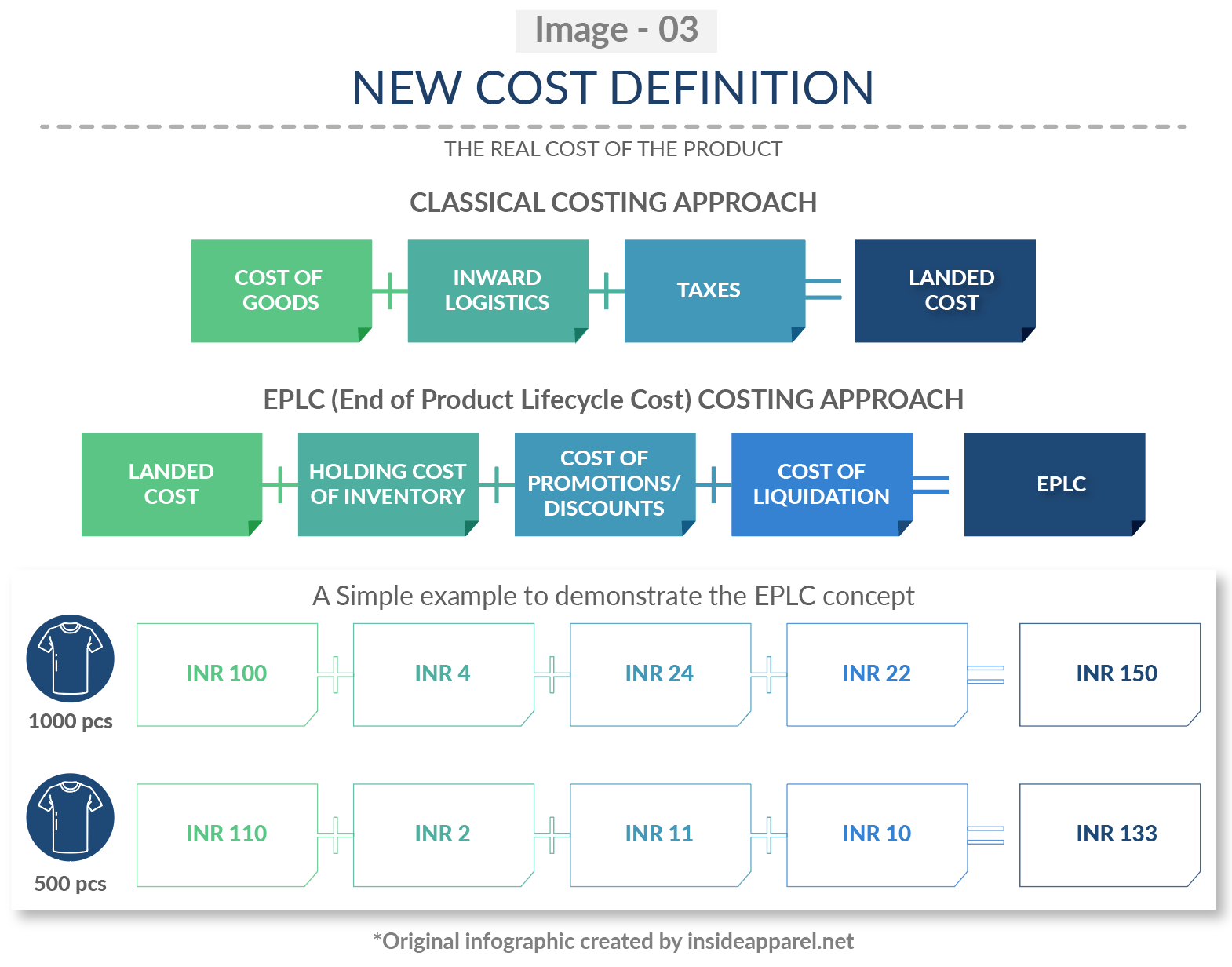

The biggest issue with companies today is how they look at product cost. The moment we shift from defining deliverables in terms of ‘landed cost’ to ‘EPLC - end of product lifecycle cost’, the whole game changes. It is explained with a simplistic example in Image - 03 below.

In the above example while it appears that at Rs 110, the product is more expensive. In reality it is actually cheaper for the company. And this is where the real problem lies with pushing L1 costs across different supply chain pipes.

What is needed is a wholistic approach to cost (defined here as EPLC) and that is an organisational objective as against simple ‘landed cost’ which is a sourcing objective. Now the moment an organisation starts mapping and reducing its EPLC, the following questions would need to be answered.

- Location of sourcing hub, ‘near-shoring’ and speed to market

- Volume of purchase or buying small lots and multiple times based on demand

- Vendor as a Curator/Fashion innovator or as only a low cost manufacturer

This in itself will re-orient sourcing teams to think differently for the company.

But having understood that sourcing functions have to move away from L1 sourcing to applying different sourcing models for different business requirements and different supply chain pipes, we need to now move to another topic, changing the very way in which we work.

MOVE TO CONSULTING FROM POLICING

Currently Sourcing and Quality teams have a policing approach to the procurement and manufacturing function. The greater the control, the happier the sourcing teams.

Where is trust? What happened to collaboration?

But the question I ask is more fundamental,

- In this new world, can companies continue to invest in very large sourcing and quality teams?

- Isn’t quality, timely delivery, the responsibility of the vendor? Then why do we need such large sourcing teams?

- How much of the work being done by the teams are value adding to the company and what part is simply ‘passing the parcel’, ‘follow up’ and ‘filling up data sheets’? Do we even need people for this work?

In the future, sourcing functions need to move to working in a manner where they are like a consulting function.

- Support vendors with becoming flexible and cost efficient

- Help brands and businesses with innovation, design and development

- Negotiations, product re-engineering, source substitutions, strategic alignments for raw materials

- Train vendors to become better at managing their own quality

In the next section, we will discuss how digitisation will completely change the way sourcing organisations will function.

GOING DIGITAL

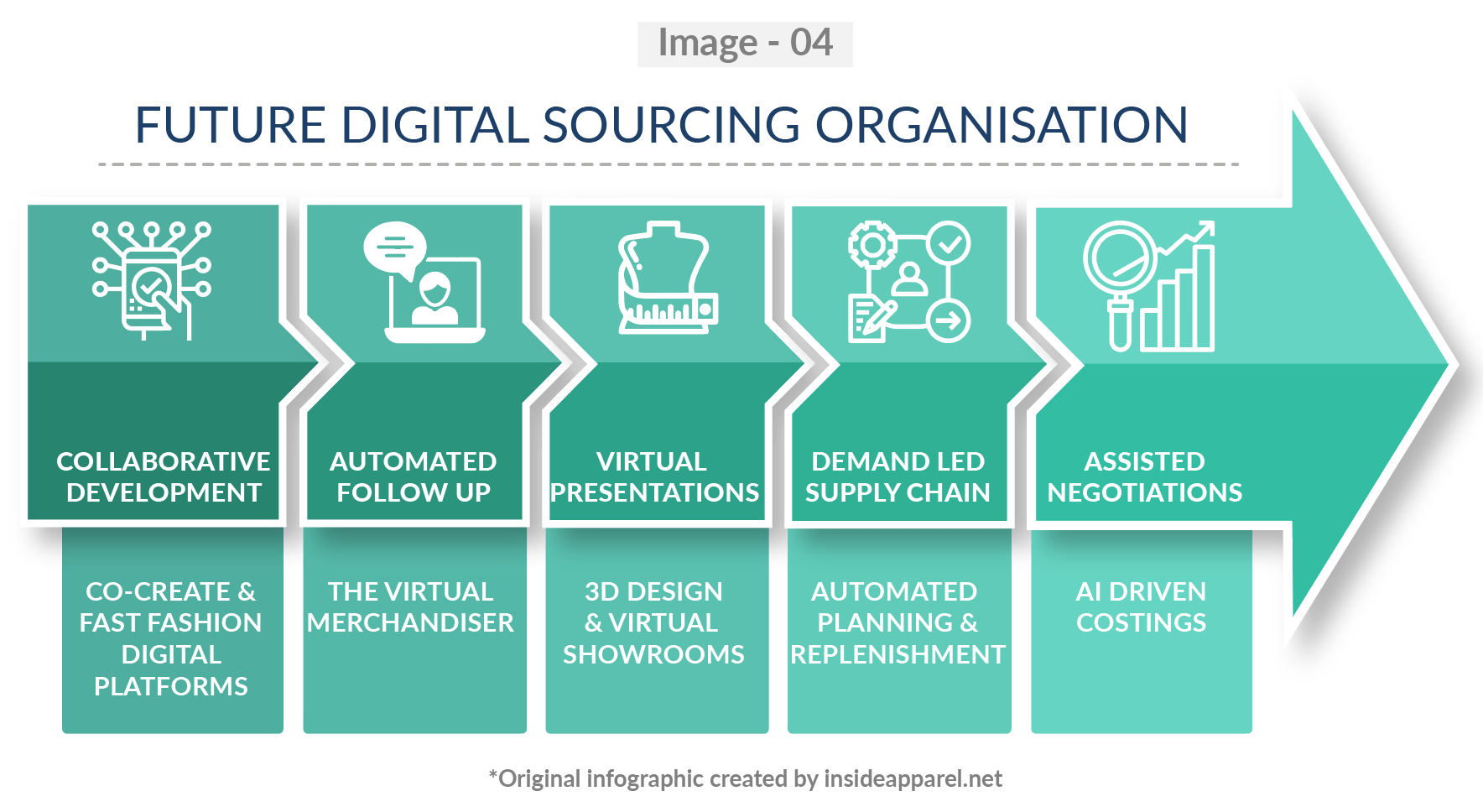

The Image - 04 speaks a thousand words. It gives a quick glimpse of how digitally companies will work in the future.

Apparel Supply Chains of the future will need to work with AI, virtual products & digital connectivity in ways that we have only begun to scratch the surface off. The real winners are going to be those who recognise this new oncoming reality and experiment with newer ways of working today, which will prepare them for tomorrow’s reality. Am sharing some ideas of what the future may contain, and it is not too far away.

INTEGRATING DISINTEGRATED SUPPLY CHAINS THROUGH UNIFIED VIRTUAL MARKETPLACES:

With the digital platforms coming into the mainstream, disaggregated components of supply chain will be integrated into a single market place. Data will be available at a click of a button to all. This ease of access will lead to an integrated view of inventory, capacities, capabilities, prices, lead times and demand enabling a seamless supply chain.

THE VIRTUAL MERCHANDISER:

A large part of the sourcing merchants day is spent on mundane activities like follow ups & documentation. A virtual merchandiser will probably be an AI based software that handles all these activities. In the future this digital merchandiser may even be smart enough to take some of the decisions itself. Such applications may soon become the main stay in the sourcing function.

VIRTUAL SAMPLING, PROCESS ENABLEMENT:

World over 3D softwares are replacing the conventional process of sketching, sampling & sample presentations. Today, the roadshows are just a click away. Virtual roadshows, digital or video approvals on design and fits are reducing months from the calendar and making business faster & agile.

DEMAND LED SUPPLY CHAIN:

The “Test & Repeat” model is going to be the future of the apparel industry. Brands & retailers will make less or opt for virtual products to test. Only the products which work will be manufactured. Quick repeat orders will soon become a reality. What sells is what will be made. Prepare for smaller lots and multiple quick replenishments.

DIGITAL PLATFORMS MANAGING PLANNING, SOURCING, QUALITY & COMPLIANCE WHILE CONNECTING ALL STAKEHOLDERS:

Future ready technology is enabling all stakeholders of the business to collaborate on digital platforms. This is shrinking the lead times & enabling everyone to make quicker decisions. And presenting a single source of truth in the whole supply chain, which will virtually eliminate hours of agonising and hundreds of man days.

A single click platform is the future of the apparel industry & adoption of technology based assistance is the way ahead for sourcing teams across the industry

CONCLUSION

The sourcing function needs to rediscover its purpose and how it can value add in this emerging new world. A lot of fashion companies today suffer from this preconceived notion of how sourcing needs to function and what it is supposed to deliver. A hard look is required at some of our most dearly held idea’s.

To quickly summarise, I would simply say

- Digital is the only way forward, and this pandemic has really brought this to light and probably started the process of fast forwarding adoption

- Sourcing needs to rediscover it’s purpose, restructure and realign itself to be relevant in today’s changing market

- Fashion companies need to relook at some of their cherished ideas about L1 sourcing and how to measure costs

What do you think? I would request our readers to contribute their thoughts and opinions in the comments section below, so that it leads to a good constructive debate.

RELATED TOPICS:#Costing,Sourcing,Apparel,Fashion,Virtual Merchandiser,Supply Chain,clothing,Procurement,brands,fashion industry,Anindya,Brand Categorisation,supply chain strategy,fashionbrands,digital,digitisation,segmentation,Sourcing Strategy,Cost Strategy,Sourcing Structure,3D Design,Co-Create,PLM,Product Life-Cycle,Virtual Sourcing,Distance Quality,Anindya Ray

Leave a comment

Our email address will not be published. Required fields are marked *

11 Comments

Eloise C. Walker Dec 28, 2023 at 13:00 pm

Wow, what a great read! I never thought a sourcing function could shift from a "policing" to a "consulting" approach. Anindya, your blog gave me a good perspective on how sourcing plays a massive role in ensuring quality, timely delivery, and responsible sourcing efforts. A valuable pre-production guide indeed!

1792Jan 24, 2023 at 09:54 am

1792

GunishJul 12, 2020 at 11:44 am

Very detailed and well written. This article outlines a roadmap on how companies should retool their sourcing function. We at Bluekaktus are great believers in digital. Digitization can dramatically improve productivity and institutionalizes experience in the company. All brands have to look at digital to improve speed to market and reduce costs.

RayanindyablogsJul 20, 2020 at 18:32 pm

Agree Gunish, companies that miss this trend today will really get left behind.

Krishna Kumar (KK)Jul 12, 2020 at 09:01 am

Very good insights Anindya. I like the way you have built the arguments for Digitalization. It is very pertinent to note that the technologies you mentioned have been around for quite sometime but our Industry never made it mainstream. For example, 3D has been around for 20 years but our dogmas stopped us from embracing this. We needed a pandemic to wake us up and smell the coffee. Keep writing.

RayanindyablogsJul 20, 2020 at 18:37 pm

Thanks KK, have always seen how you have pushed for adoption of new technologies and worked with brands to take them into the future. Today, I feel its no longer an option. Thanks for sharing your thoughts.

Prashanth HVJul 11, 2020 at 15:14 pm

Agree on futurist approach on Sourcing and quality functions. This pandemic has taught us many new ways of working which we never thought it is possible. Not only these two functions whole retail industry has to rethink the way it operates. I expect you also write about other functions in the industry and like to know your view what would be the new age retail operations, what things need to be changed are improved.

Sanjay LalJul 11, 2020 at 15:07 pm

Today State of the Retail industry can be described with two words: “Disruption” and “Uncertainty”.

Sourcing is defined as the process of determining how and from where manufactured goods or components will be procured.’

The main motivational force to do sourcing of garments/fabrics is to give the highest level of satisfaction, at low production cost. Today’s business strategy is shifting the certain operations from apparel value chain to low cost, speed to market and takes competitive advantage to enhance the profit margin of the company.

A good sourcing merchant must be totally tuned to various factors like:

Trade War – The recent trade war between USA and China which has greatly shifted the business dynamics. The Battle for Margin—As we know the raw material costs are going to eat into margin, as well as logistical costs, cross border commerce and returns. Fulfilment companies will have a hard time trying to figure out the way to beat it. Sustainability to Traceability--consumers have become increasingly aware of fashion’s impact on the environment. As a result, many are deciding to spend their money on cleaner, more conscious brands. ' Green washing ' has become a major problem, as many brands are over expoliting the interest in sustainability, using it as a buzzword marketing strategy whilst still maintaining the existing wasteful model of production. Greater transparency is called for by consumer groups who demand to knaow the water footprint, carbon emissions and factory workers right and welfare of the garments they buy. " Traceability ", a word that should replace " Sustainability ". Without traceability, you cannot be sustainable. R&D Materials Revolution--more innovation in sustainable materials will be on the agenda for the company in the coming year. Globally, there is a big push in moving away from petroleum based plastics, dyes and polyesters, which means to be pioneered by smaller brands and / or start-up. Heading into 2020 many predict a heavy adoption of natural materials like organic cotton, hemp and linen, by mainstream brands. Additionally, another bio-based fibres are due to take prominence for instance, the wood pulp derived Tencel Sorona - a performance fibre made from fermented sugars, as well as fibre from recycled plastics, banana, custard apple, while increased innovation in new materials continues. The New Reality for retail--The reality is that 2020 will likely see more store closures, as traditional companies may continue to lose out, with more finding themselves on the road to bankruptcy. focus on a localized brick and mortar stores, and personalized customer experience, which will mean a ramped up presence in neighbourhoods with small format stores that speak to the local community. They physical landscape of commerce is being changed. Warehouses are taking over from shopping malls. Example, Amazon and Flipkart are investing heavily in warehousing and distribution. In 2020, sourcing that focus and succeed in product innovation, creating unique customers experiences and achieving genuine sustainability goals, will come out better prepared for the challenges of the future. No longer obsessed with abundance, better, and cheaper products, todays customers look for meaning in the customer experience and identify with brands that represent unique and authentic deeper values. The triple bottom line is People, Planet, Profit - in that order. The indicators are everywhere, we now have a real backlash against fast fashion and discount retailers. We are seeing a rise in recycling, upcycling, vintage, secondhand. While I fully subscribe to the Digitization in the Supply Chain and companies investing heavily into the software, it is left to be seen how the vendor will adopt the same. How the vendor sync with the retailer. It is also true that every retailer will be careful of not exposing or sharing the data with vendors. On the other hand, there will be a risk of data theft, hacking, virus attacks from third party system forcing the retailers to invest heavily in protection. This means the cost of the digitization going up for the vendor. Retailer will be foolish to think that after passing the digitization he will have a monopoly on the vendor. Sourcing knows vendor cannot survive on one customer and manufacturers for number of other retailers. This translates that the vendor will need similar digitization with other customers, resulting into the cost increase for the vendor. Is it financially viable for the vendor? This digitization also means the vendor will have to hire specialized manpower to read, understand and decode the figures coming in. While it is good that the digitization will bring in transparency in the business, will speed up the process. The full impact of this digitization will be achieved only when the stitching process is also automated. Robots take over from tailors. Are the factories geared up to spend this sort of money when survival is becoming a challenge? In an industry undergoing real-time demand collapse and seismic supply shocks, where does sustainability sit? Post-pandemic, there will be a conundrum; consumers are thinking hard about their choices and the need for a more sustainable way of life after the Kovid – 19, making choices based upon values. On the other hand, many in the apparel industry will not have the resources to invest in transparent supply chains and responsible sourcing programs in a meaningful way. Undeniably, apparel sourcing is becoming more challenging. Sourcing once focused primarily on cost, must now take into consideration several other important factors. Corporate social responsibility is more than a buzzword: leading apparel companies are working to improve standards throughout the value chain and adhere to sustainability strategies consistently. There is a lot of discussion surrounding transformation and change in the retail sector, but fundamentally, businesses are not changing fast enough as we still see old cultures, old philosophies and old practices that dominate the boardrooms of the biggest companies in Retail.RayanindyablogsJul 20, 2020 at 18:39 pm

A fantastic piece, worthy of being a blog on it's own right. Would urge all to read.

Abir BasuJul 11, 2020 at 13:01 pm

Sir, you have addressed the key aspects , the most important is that at times sourcing because a data management function, and so much time is spend on data, that the product which should be the key focus area is lost, data is nos and in pursuit of nos , the product is lost.. the discussion should revolve only around the product and innovations which would as a end result show up on the nos also. In any category the options and innovations exist in the market, it is only with focus on product can value be added to the product and which eventually with show up in nos.

RayanindyablogsJul 20, 2020 at 18:41 pm

Absolutely Abir, with you all the way.