THE FUTURE SERIES

Article 4 of 6

The Future of Fashion Buying

This is the 4th article in a series of 6 articles exploring the changing world of the fashion industry and what it means for its various stakeholders. In this blog I shall be discussing the evolving role of the Buying and Merchandising function in the Brands and Retail companies.

For the purpose of this article and to keep it simple, the term ‘buying’ shall refer to the buying, merchandising, product management and planning functions. The term ‘brands’ shall refer to both fashion and retail brands.

Some other topics, like the changing relevance of seasons, product strategy, fashion vs. trends, multiple go-to-market calendars, has already been covered in the previous article, and hence I am not touching upon it again.

But before we start, let’s look at why this central function needs an overhaul? As we discussed in the first article, fashion brands are no longer in the drivers seat, they don’t dictate trends any more. So brands find it increasingly difficult to forecast sales accurately in these uncertain times and this leads to:

- Inefficient inventory build up and reduced availability of right merchandise

- Leading to lower sales, higher inventories and higher markdowns

So in this article, I will talk about

- moving to inventory planning linked to sales,

- building a bestseller led strategy, through ‘test and repeat’ merchandising,

- the importance of defining the product architecture by supply chain logic,

- supported by a segmented approach to OTB management,

- augmented by dynamic pricing and finally

- the use of AI

to improve inventory efficiency and increase profitability for brands in the future.

Hence let us explore how businesses can be more robust and closer to their consumers, starting with removing an anomaly in the thinking that drives planning today.

Move from ‘Inventory made for Planogram’ to Sale based Inventory

Planograms are the holy grail of retail. There are numerous AI driven softwares that help visualise and manage this complex architecture. Unfortunately brands use a cluster of different planograms to plan storage and display in different types of stores and then use that capacity for filling the store with inventory.

Planograms should be viewed more as display optimiser to enable higher sales through better visibility rather than an inventory tool. Modern store fixtures are flexible and allow for open or stacked displays enabling reducing or increasing inventory holding capacity.

Hence inventories must be reflective of sales and not planned for filling up fixed planograms. Once the inventory is defined (ideally based on weeks cover), then planograms should be used to optimise visibility.

I have often found this extremely misunderstood concept amongst buying and planning teams which keep filling up inventory in stores without it having a direct link to sales.

Having understood that the first step is to buy what can be sold as against buying to fill display areas or to complete the offering, we now move to discussing more fundamental changes in the operations of the Buying and Planning function.

Building a bestseller led strategy

This is probably the only industry where goods come in with a deliberately limited shelf life as we have pre-decided the products fate. Imagine if car models had to be taken out every six months to pave the way for new cars, what would happen to their inventory and markdowns?

However, the question I ask is, is this pre-defined life cycle relevant any more? Brands define their product line based on their understanding of their own positioning and what they perceive the consumer will buy from them.

But, the reality is that post launch the market clearly repositions a brand in terms of how they perceive it and what they want to buy from it. And we know this through their bestselling products.

This is what I refer to as the ‘Bestseller strategy’ for brands. This means that every product that becomes a fast moving bestseller should be immediately moved to a replenishment pipe – with defined threshold ROS (rate of sale), below which it should be discontinued. This is the way all other industries operate – but why not fashion?

Bestsellers should meet three qualifying factors,

- it should be a high velocity product

- it should be possible to be put on a replenishment pipe

- it should have wide acceptability across channels and geographies.

Of course this needs a calibrated approach – for e.g. faddish products, long leads etc., cannot be taken on replenishment even if they become bestsellers – may be repeated, but not replenished.

Basically, do brands need to rethink core as well? Should their bestsellers become core, rather than piling up inventory offering products which are ‘classic by definition’ as core, but no one is buying? These are questions which I would like you the reader, to consider and comment on.

But the question then becomes, how do brands consistently score hits or in other words bestsellers?

Move to a ‘Test and Repeat’ merchandising strategy

Buying is as much art as it’s a science. Some of the best buyers are those who can smell a bestseller way in advance and take a punt on the numbers, thereby maximising sales and profits. But these legendary buyers are hard to come by.

Here, I must mention that there are many AI based tools that promise to rate or predict product saleability or identify trends. Well this may help in guiding product creation, but the actual hits can only be assured with requisite testing.

So how do companies keep scoring hits? Social networking provides an amazing opportunity as does sample testing in select channels.

Here are a few tips:

- Create a limited test group for testing new products, connected through social networking.

- Keep launching new products, styles in that group, get it rated, tested & based on that decide on what to proceed with.

- This creates fertile ground to keep innovating and experimenting with trends. It becomes even more viable if designs are presented in 3D where the customer can’t make out that it is not a real sample, allowing for quick decision making even before test ordering.

This is a simple solution to creating more hits through testing. The trick in quick go-to-market and product launch is in operating with platformed raw materials. This is today being used by most tech savvy brands – a simple way to keep scoring ‘hits’ in the business.

But how do we build these strategies into our product architecture in a way that optimises supply chain.

Building the product architecture based on supply chain pipes

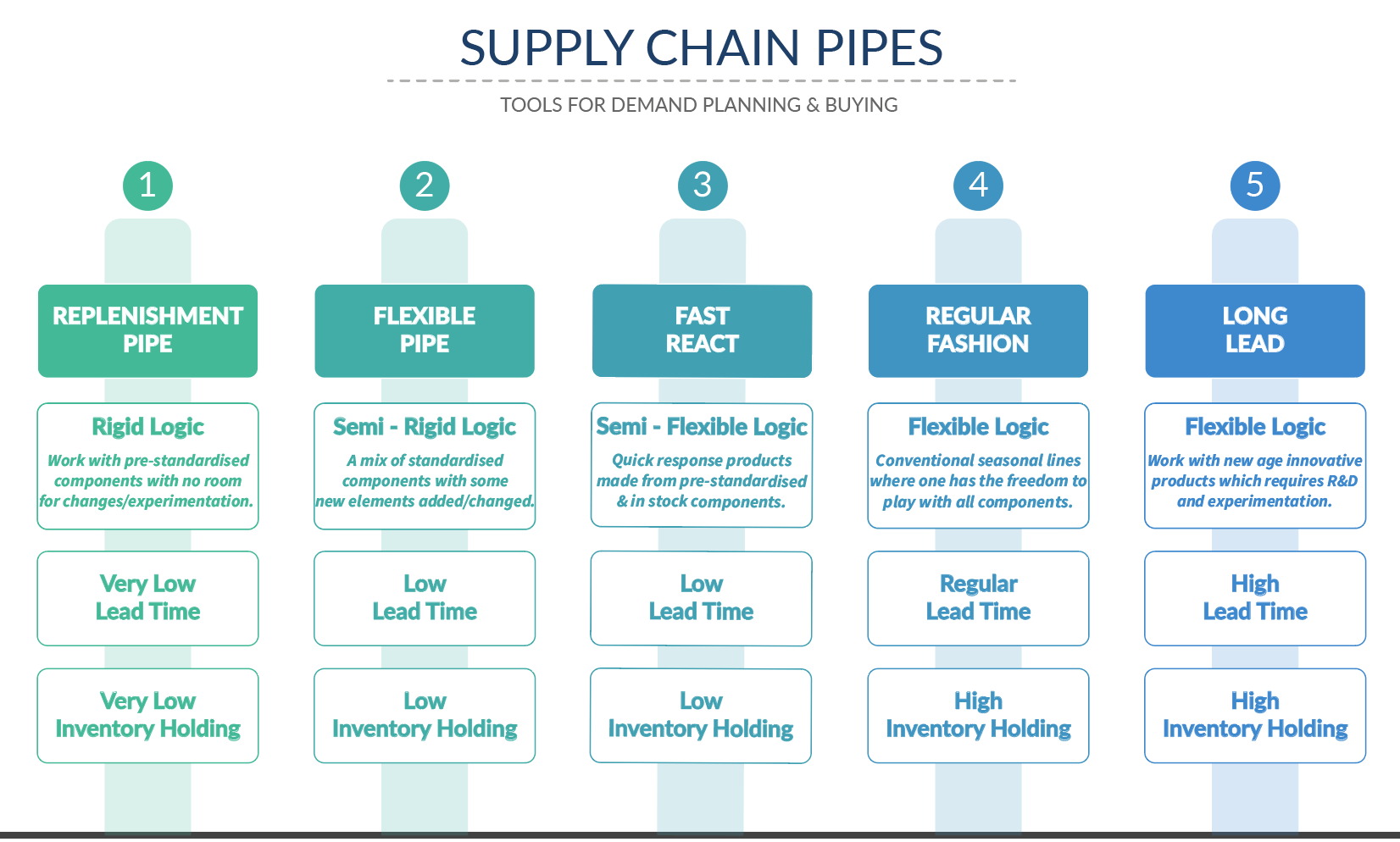

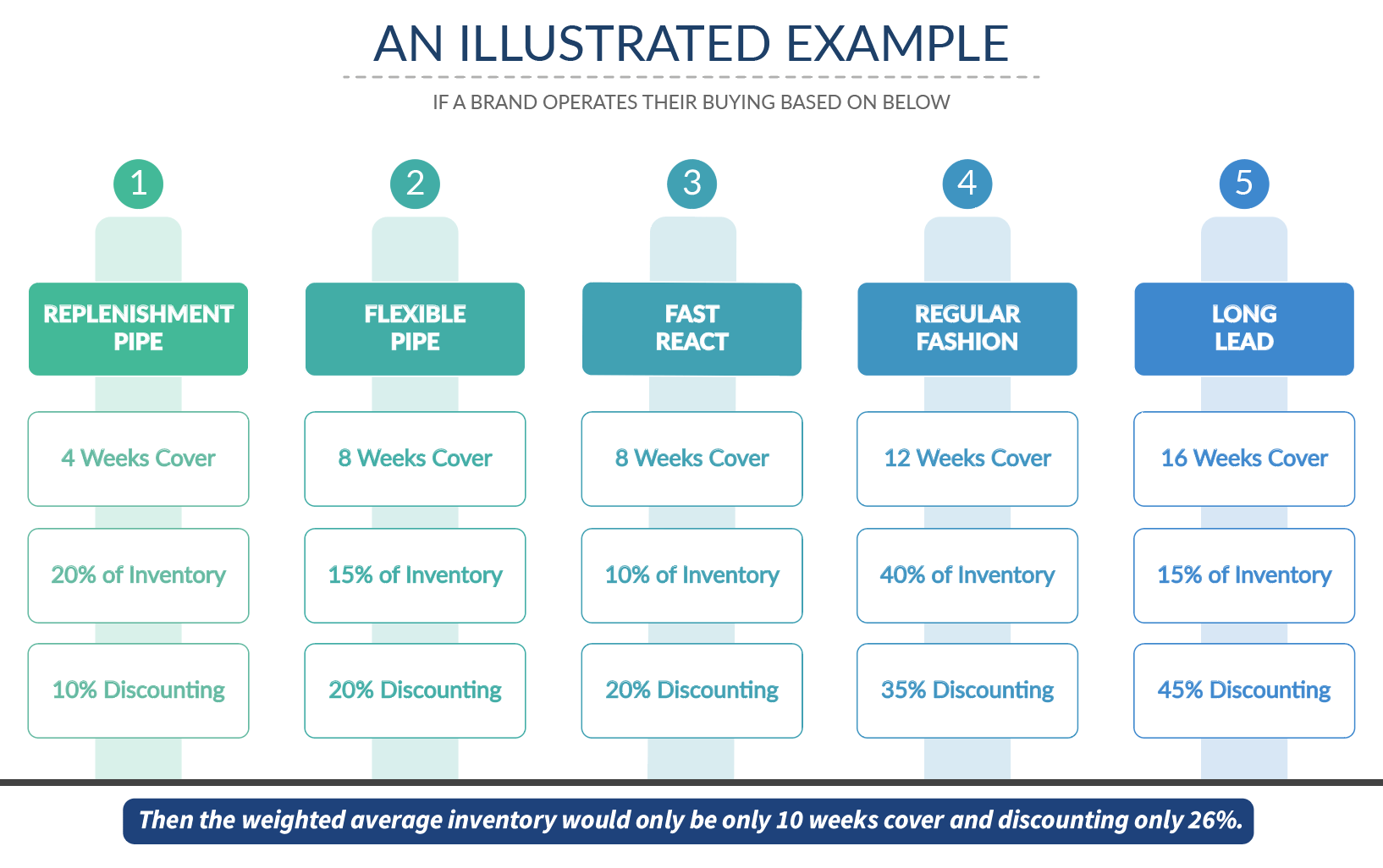

The key to this is really marrying back-end supply chain with demand planning and buying. Let’s first understand what the supply chain pipes (clustering supply logic through different rules and lead times) are. They can be simply explained as in this infographic:

It’s a simplistic working and is very easy to understand. But why is this not followed by most companies? Well, two reasons (a) because of multiple channels – operating with their own demand rules and (b) since the product architecture is not made with this logic in mind.

The buying team holds the ‘can’ on this and getting design, supply chain, demand planning and sales teams to align all the external stakeholders to ensure that this works, is the key to becoming inventory and margin efficient in the future.

The product line architecture must be made with these pipes in mind and different calendars and rules must be applied to product design, order trigger and go-to-market strategy to make this work.

But to try all this we need to have OTB, how does that get sorted?

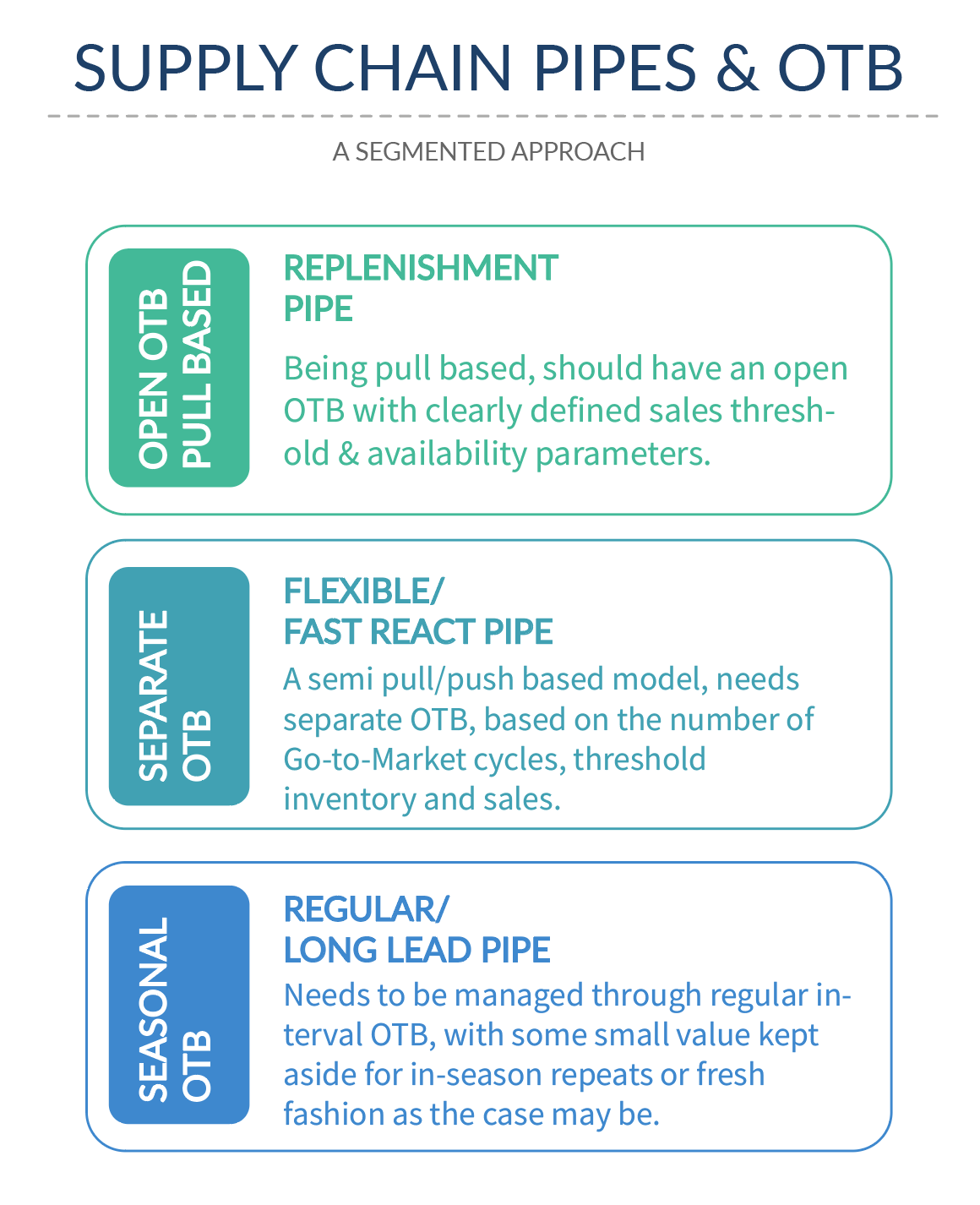

Segmented approach to OTB management

The most dreaded word for the buyer is OTB or Open-to-Buy. There never seems to be enough money available to buy what is truly needed. The best approach is to manage OTB for each supply chain segment differently, as explained in the infographic.

The issue with managing ‘buy’ values is that these segments are mostly not managed separately. This leads to unjustified spends in each segment, and hence does not allow for ‘buy optimisation’.

While this increases the buying inefficiency, how does one then reduce markdowns, keep inventory less and freshness high in the channels?

Move to Dynamic Pricing

Or should I say dynamic markdowns. This means tracking products and their ROS (Rate of Sale) rigorously and start marking down products basis how they are faring, without waiting for end of season. This dynamic pricing model should:

- Allow for different locations, colours, sizes to sell at different prices based on product performance.

- Be dynamic and the markdown should keep changing with time and ROS.

- Also sometimes incentivise future buy’s through coupons instead of just markdowns.

This will result in increased sales, less inventory during clearance and lower markdowns. This lower inventory during clearance will allow brands to sell fresh merchandise in the hopes of catching early bestseller trends and increasing trading weeks for fresh merchandise.

But is this level of detail humanly possible?

The Use of AI

Technology is changing the world and it should also be used to bring precision in the ‘Buying Decision Making’ process. The best area’s to use this is:

- Dynamic Pricing

- Predictive ROS (Rate of Sales)

- Bestseller Management aligned to Supply Chain Pipes

- Merchandise Financial Planning and OTB management aligned to Supply Chain Pipes

- 3D design for improved speed to market and testing

This use will free up the Buying team’s time and enable them to value add in other area’s like innovation & promotions to name a few.

Conclusion

We may all feel that this is all common sense. Well yes, but there are some legacy concepts in play in the industry today that needs to be challenged going forward. And that is what needs to change. To recap,

- Plan inventory linked to sales, not to display and offerings.

- Stop looking at the business with a one size fits all solution to calendars, product architecture, product launches, OTB management, markdowns and clearance sales.

- Relook at product lifecycles – decision to take a product off should be based on rate of sale rather than some perceived time period called season. Imagine if best selling car models were taken off shelves every six months just because the car company had to offer new line-ups every six months.

Each product on its own merit, that is the only solution to higher efficiency.

I hope this discussion has been interesting and that it has made us question some of our profound beliefs in the accepted way of working. Do share your thoughts in the comments section below and enrich this discussion.

RELATED TOPICS:#Sourcing,Apparel,strategy,buying&merchandising,brands,fashion industry,Fashion Brands,Brand Strategy,Anindya,Fashion Lifestyle,future of buying,inventory,bestsellers,supply chain strategy,product management,OTB,Anindya Ray

Leave a comment

Our email address will not be published. Required fields are marked *

13 Comments

Prashanth HVJul 05, 2020 at 21:22 pm

Very good thoughts and great ideas for the industry which is struggling today. In my view, there are several points that is important while discussing buying. 1. Channels 2. Sourcing lead times 3. MOQ 4. Flexibility of management Channels: today brands are present in various channels. Each channel expects different kind of merchandise and sales price and margins. If all the stores are owned by the brand then many things can be controlled. But if there is pressure from multi brand outlets and department stores, then you ha e to succumb to there pressure to allow planogram and discounts. If the norms are not met by the brand then one is forced to walk out. Sourcing lead times and MOQ are very much important when we consider less inventory and go for faster replenishment. At last flexibility of management to explore new ideas and take risks is most important.

RayanindyablogsJul 20, 2020 at 18:10 pm

Hi Prashanth, you are absolutely right. I have also said the same for e.g. demand planning takes into account the various channels and their requirements and hence, most times is unable to meet supply pipes logic or planogram logic. But the important bit is to recognise what the ideal way is - if that is clear, then the company needs to align channels and demand to as close as possible, to optimise both availability and supply. This covers the 1st three points. But to scatter supply planning completely is and cave in to every demand requirement without an attempt at alignment would be folly. I don't know what you mean by 'flexibility of management'? Most of the times management is too flexible and that leads to ignoring the supply pipes and this leads to higher inventory and inflexible supply chain. It is important for companies to understand the benefits of planning properly and managing the supply pipes - it will also help their channel partners with sales and their inventory flows. To have a perfect system may be difficult, but to engineer product offering and demand rules closer to that is optimisation of the whole supply chain.

Himanshu SJul 05, 2020 at 20:59 pm

Dear Anindya, It’s a very good read. Few pointers: along with the dynamic display, a lot of retailers are moving towards hybrid model retail. Today the instant gratification is not the primary requirement of the customer, hence with the use of large screen displays, using any of the end less aisle tools will further keep a check on inventory and yet maximise sales. Key to success would be to consolidate inventory at inventory hubs and make them visible to multiple stores. This would reduce multiple inventory holding points. The impact of Covid to the over all mindset of customers will also make brands and retailers Re-think about Fashion matrix. People would consume products that are seasonless and sustainable. Market in coming years would distant itself from Fashion that is short lived And move to products that are made to last.

RayanindyablogsJul 20, 2020 at 18:12 pm

Bang on Himanshu. Thanks for sharing your inputs. Please do keep discussing the issues in this forum. It enriches the discussion.

Steephen AnthonyJul 05, 2020 at 19:12 pm

Dear Anindya sir, It is Very unconventional approach and bond step if executed, especially the point of ‘ procuring the goods based on rate of sale rather than to fill the store’ . Very good concepts

RayanindyablogsJul 20, 2020 at 18:12 pm

Thanks Steephen

Nazmul HuqJul 05, 2020 at 17:37 pm

Dear Anindya sir, Very well covered all areas and superb depth of insights. I wish this brilliant insight could be an actionable method. Excitedly waiting for the rest articles. All the very best wishes for you.

RayanindyablogsJul 20, 2020 at 18:13 pm

Thanks Nazmul

Ram SubramaniamJul 05, 2020 at 08:23 am

I liked Anindya questioning the basis of two assumptions of the fashion Industry. 1. The logic behind a planogram and if it actually works. I am personally tired and sick of not finding a S or a M or a L frequently despite being attracted by the overall display!! - 2. Do we need to follow the fashion seasons of the west in India even though it is almost one single season in most of the country- through the year? Ideas to really think about!! Blog makes a nice fast read! Subramaniam

RayanindyablogsJul 20, 2020 at 18:18 pm

Thanks Subbu

GunishJul 05, 2020 at 06:03 am

Very comprehensive and actionable advice. This would require a complete overhaul of the structure of the buying and sourcing teams. And how they are incentivised. For example can buying be incentivised on ROS? Also, how does a brand maintain it's TRUE essence? For example is FRESHNESS a desired outcome? Like Zara. Should retailers create artificial scarcity? Is that a good strategy?

RayanindyablogsJul 20, 2020 at 18:25 pm

Zara created a model 3 decades back which even today has not been replicated because they created a culture to manage their ideology. Everyone knows how they work, it is just that no one does it that way. To answer your question, the company/brand must be very clear of their objectives. Then design their B&M strategy around it. The principles don't change, just the degree's by which we manage the various aspects of supply chain do. The important thing here is to be consistent with the approach. Zara has been consistent. Thanks for your very interesting questions. Do find time to share some articles exclusively for our readers.