If you are in the Apparel Business, you will very well know that things can go wrong at any time.

When we stepped into the apparel trade, there were no classrooms. All my contemporaries who came into trade were from different walks of life. Only some textile courses existed from which the graduates joined the textile mills.

Things have changed!

Now the youngsters are spending years in classrooms and theory. They are taught how things work, what steps to take, and how to create workable systems to avoid problems.

Let me tell you from 30 years of experience in the trade that it is all theory. In the classroom, everything works, and for every problem, there exists a solution.

The reality, unfortunately, is somewhat different. In the real world, things go wrong, and most problems have no solution.

Often the only solution is to choose the best from a bunch of bad alternatives.

Fabric arrives late or in the wrong quality, in the wrong color, or fails tests, or never arrives. When disaster strikes, what do you do?

There are rules. Usually, professionals require about 1½ lifetimes to work out these rules. For the first 20 years, the rules appear to be totally irrational. For the next 20 years, most professionals lack the courage to follow the rules. By the time the professional understands that the rules actually work and that these rules offer the only solution, he or she is 95 years old and no longer in a position to do anything about anything.

I learnt this in a ridiculously hard way. Let me tell you an incident.

In the early ’90s, auto/power loom jacquard fabric was in vogue. Europe was buying it in a big way. So, my customer placed an order of 20,000 meters (10,000 meters each in two colorways). This order was placed with a weaver in Salem. TNA was on track and on the appointed date I flew to Salem via Coimbatore for inspection.

I was happy to be able to ship the fabrics to Bangladesh on time.

The first colorway was inspected and the fabric was in acceptable condition. We decided to inspect the second colorway after lunch. All were happy, enjoyed simple lunch, and went back for inspection. The second colorway was offered for inspection. Suddenly, I realized something was amiss. The original design and desk looms were called. I could feel something was wrong but could not put my figure on it. By now owner and weaving in charge also joined in the inspection. I went ahead with the inspection but had a nagging sense that something was wrong. Finally, I asked the mill to spread both the colorways together. And behold, the jacquard pattern in one colorway was woven in the opposite direction. This became a completely new design.

The funny part is upon investigation, it was found that the person who set the jacquard on the loom was drunk in the night resulting in the wrong setting of the pattern.

We had no time to start the whole process afresh. Buying yarn, dyeing, weaving, etc. So, what do I do?? I picked up the phone and made a call.

I am sure no school will teach you how to resolve such a crisis.

It was then the 10 cardinal rules were worked out:

Rule 1 - When disaster strikes, never think.

Thinking is bad. Thinking leads to conclusions, such as ‘This is not too serious, or worse, ‘The buyer might never see the problem’. This is called living in denial. Good factories have standards. Either material meets those standards, in which case life goes on, or materials do not meet those standards, in which case you have a disaster.

Your only decision is whether the material conforms to the factory standards. This is like either you are pregnant or not pregnant. There is no midway, either you are, or you are not.

Rule 2 - Immediately notify the buyer.

The operative word here is immediate. Do not wait for tomorrow in the hope that things will look better the next day. Either thing will not look better, which is not good because you will have lost a day, or things will look better which is worse because you are now moving into denial. Telephoning is good. Telephoning the buyer at 9 p.m. at their home is even better. It is immediate and therefore keeps everybody focused on reality. It also shows your buyer that you take the problem seriously. Remember, all problems are evidence of incompetence. You want to ensure that the buyer looks at this disaster as your once-in-a-lifetime lapse. The very worst possible case occurs when the buyer hears about the problem through a third party. This is proof positive that you are incompetent and should not be trusted with any future orders.

Rule 3 - Make the buyer your partner in the problem.

Remember, you may have caused the disaster, but your buyer does have a problem. Of course, the buyer wants to blame you, but it also needs a solution. You want to be seen as more than part of the problem; you want to be seen as part of the solution. Your opening words on the phone should be, ‘We have a problem.’

Rule 4 - Never minimize the problem.

Always slightly exaggerate. This rule requires some explaining. There are two reasons for this rule and they both begin with the same disaster. In this case, your fabric arrives late, and this delay will result in late shipment by about 15 days and further into stock. As far as the buyer is concerned, late garment delivery means the factory is run incompetently. The one thing you do not want to do now is minimizing the problem by telling the buyer that stock shipment will be delayed only 10 days (hoping to make back the lost days by working overtime.) Saving five days will not alter the buyer’s perception that you are incompetent. It only increases the probability that you will be late once again. By the same logic, telling the buyer that you will be 15 days late leaves you no leeway. You must do everything possible to ensure you are not late a second time. The easiest way to do this is to ask for more time. As far as the buyer is concerned, there are no degrees for 1-day late, 5-days, 20-days late – you are just incompetent. Adding a further five days to your existing 15-day delay ensures that you will not be late a second time. The buyer does face real problems caused by your delay. Anything you can do to help solve the problem will at least partially compensate for the fact that you caused the problem in the first place. If you want to keep the buyer, you must show real results. Telling the buyer that its goods will be delayed by 20 days but then saving 5 full days makes you, if not a miracle worker, then at least a magician. Of course, like all magic, this feat was accomplished by smoke and mirrors. By the way, slight exaggerations are good. Big exaggerations are risky. You do not want the buyer to cancel.

Rule 5 - The customer is always right.

Every industry has this rule, but none takes it as far as the garment industry. We believe the customer is right even when the customer is wrong. We do not even care about right or wrong, we care only about the customer or no customer. Others have the luxury of standing on principles. We in the garment industry lost that right the day we realized that none of us are indispensable. There is a long line of factories just waiting to replace every one of us.

Rule 6 - The factory is always wrong.

If the mill ships late, if the color is not the same as the approved lab dip, if the mill substitutes the wrong quality, if the fabric fails testing, it is your fault. That is obvious. That is what sourcing is all about. Once you have agreed to source the materials, you are responsible. Furthermore, your responsibility extends beyond problems caused by the mill. They extend to problems caused by the buyer as well. If the fabric is late because the buyer locked your lab dips in a desk drawer and went on a two-month holiday before sending approvals and is inaccessible, this too is your fault. Insurance companies may have special clauses in their policies obviating all responsibility in the event of war or what is termed ‘Acts of God’ (force majeure). Unfortunately, the garment industry has no such protection. Let us say the mill loaded your fabric aboard the ship Titanic. The ship hits an iceberg and sinks, carrying to the bottom of the sea 1,196 people plus 10,000 meters of fancy cotton twill. The buyer will send you a note of condolence for the drowned passengers together with a claim for late delivery of garments. Is this unfair? Definitely! Should you pay? Yes! Why? Because your competitor would pay and if you want to compete, you must offer the same or better service as your competitor.

Rule 7 - The factory/sourcing must completely solve the problem.

Telling the buyer that you will accept cancellation is not a solution. This does not help the buyer. You must overcome the problem. For example, late fabric delivery can usually be solved by shipping the stock garments by air. Poor fabric can often be solved by flying the replacement fabric to the factory and then shipping the stock garments by air. These solutions are so obvious that buyers often will not even suggest them. They already assume garments for late shipment will arrive by air.

Rule 8 - If you cannot completely solve the problem, you pay a claim.

Remember, it does not matter who caused the problem. Your only question is: Do you want to keep the buyer? You have two options:

– I want to keep the buyer; therefore, I will pay the claim.

– I do not want to keep the buyer; therefore, I will not pay the claim.

It is worth repeating here once again that right and wrong do not enter the equation. Take that buyer who went on a retreat. If you want to keep the buyer, you pay the late claim with a note telling the buyer that you well understand that their religious enlightenment is more important than lab dip approvals. If you do not want to keep the buyer, the situation is reversed. For example, if I had a buyer that I did not want to keep, and if through some inconceivable series of mishaps, I produced exploding T-shirts that detonated upon contact with human skin, I would not pay a claim. More likely I would put in for a supplemental debit note charging the buyer for special finishing.

Rule 9 - You do not pay consequential losses.

Finally, here is a rule that favors the factory. Losses arise whenever the buyer is unable to sell the garments at full price because of errors on the part of the factory. Late delivery, poor quality, and poor fit can all result in real losses. The real loss is the difference between the amount the buyer paid for the garments and the amount received when the garments were finally sold. The worst-case scenario occurs when the buyer is unable to sell the garments at any price and therefore the loss equals 100% of the garment cost. In these circumstances, late delivery might result in real losses, but, ironically, failure to deliver at all results in zero real loss as the buyer neither receives nor pays for the garments.

This situation gives rise to what are known as consequential losses, the indirect losses which occur because the buyer did not have the right goods at the right time. This includes lost profit.

Because gross profits in the apparel industry are so large, being charged for consequential losses can kill a factory.

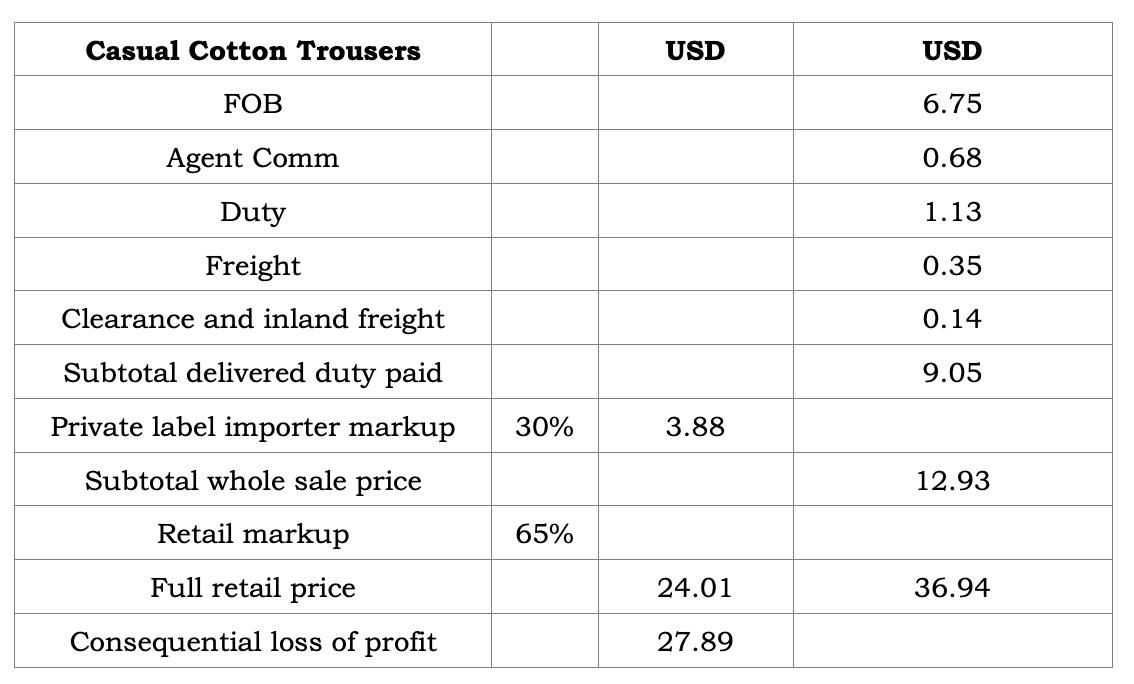

Take an example of the casual trousers shown in the costing below. In this instance, the garments were ordered by a private label importer who in turn shipped the garments to a retailer.

The factory was paid $6.75 FOB per unit. The agent took a 10% commission (could be anything as per agreed terms) on the FOB price; then the private label importer paid the sea freight, the import duty, the customs broker’s fee and local transportation.

At this point the garment cost $9.05 per unit.

Now the private label importer adds a 30% markup (markup percentage can be higher or lower). This is not the same as adding 30% to its cost which would work out to $2.72 per unit.

Rather, the gross profit or markup is 30% of the price for which they sell the garment (30% of $12.93 = $3.88).

The retailer now adds its 65% markup (65% of $36.95 = $24.01).

The trousers, which cost FOB $6.75, now retail for $36.95.

The potential loss of profit, for both the importer and the retailer, is, therefore, $27.89 ($36.95 less $9.05 rounded off), a little over four times the FOB price.

Fortunately, in our industry, in most cases, consequential losses are not charged. As a rule of thumb, a factory will go so far as to give the buyer the garments free of charge. That is the normal limit. There are two important exceptions where consequential losses are accepted.

Deadly garments. Ours is a serious industry and the people in our industry are serious people. We speak of late delivery and poor quality as disasters and canceled orders as tragedies. We also tend to exaggerate. In an industry where a company may deal with thousands of styles in any given year, mishaps such as an ill-fitting garment or an incorrect color are expected and accepted as a normal part of doing business.

However, occasionally a garment goes beyond the limits of normal defects and is a danger to the wearer. This includes cases of excessive flammability or use of caustic chemicals, of particular importance in children’s and infant wear.

Factories producing these types of garments simply cannot afford to take risks or cut corners. The professional must make full use of internationally recognized testing laboratories, such as Société général de surveillance (SGS), which employs specialists to ensure that all materials conform to international standards and those local to the importing country and the buyer’s requirements. Often the testing laboratory is more aware of relevant product legislation and any health and safety regulations than either the buyer or the factory.

Advertised garments. A retail store advertises a particular style in the local newspaper – not an uncommon occurrence. Factories producing these garments take pride that one of their garments appeared in an international publication and often hang copies of the advertisements around the factory to impress customers and to motivate their sewing lines.

All factories recognize that those advertised styles must be shipped on time. They are also aware that if the garments are not in the store on the day the advertisement appears, the buyer will never do business with the factory again. However, few factories are aware that if an end consumer arrives at the store looking to buy the advertised garment and the goods are not on sale, every end consumer has the right to sue the store. In the United States, litigation is almost a national pastime; there are very few factories today that can survive a class action suit.

Rule 10 - Keep the customer.

Successful factories recognize that continued profit and long-term success are not about the order or the FOB price.

Some of you may wonder what happened to the jacquard wrong fabric. Was the issue resolved or was it a dead loss for the factory and buyer?

Well as I stated above, I picked up the phone and told that we have a problem with the fabric. Since I run a Buying House, I had to see that somehow both parties, factory, and buyer do not lose out on business. After all, it was not an intentional doing but one poor man who perhaps in the heat and exhaustion did the mistake. I explained to the buyer the correct position. Also told him that the fabric was clean to be shipped but now he had two different designs rather than two colorways.

It was agreed that the original colorway will be shipped. The factory will air yardage of the second colorway to make 10 shirts. Buyer will in turn make the samples and send them to their retailers to get feedback. If the retailers accepted, the fabric will be aired at the factory’s cost. If not acceptable to retailers, the buyer will help to somehow sell the garments, even at a discount.

After 15 days the buyer came back that the retailers liked the new design and were ready to take the shirts. The fabric was shipped by air to Dhaka.

What is important is the relationship.

In our business, the relationship with the buyer is everything. Once you recognize this, the other nine rules become rational, reasonable, and obvious.

RELATED TOPICS:#Apparel,Sanjay Lal

Leave a comment

Our email address will not be published. Required fields are marked *

40 Comments

Кто первым придумал алфавит?Oct 30, 2023 at 03:26 am

I like the valuable information you supply to your articles. I'll bookmark your blog and take a look at again here regularly. I'm somewhat certain I will be told many new stuff proper here! Best of luck for the following!

209 primersFeb 23, 2023 at 21:39 pm

It's going to be finish of mine day, except before ending I am reading this wonderful paragraph to improve my know-how.

Sport bettingJan 26, 2023 at 10:00 am

Sports betting, football betting, cricket betting, euroleague football betting, aviator games, aviator games money - first deposit bonus up to 500 euros.Sign up bonus

DonaldJan 26, 2023 at 03:45 am

%%

Accident Compensation claimsJan 23, 2023 at 00:00 am

%%

Wild9.OrgJan 22, 2023 at 19:38 pm

%%

Mesothelioma attorney munroe FallsJan 22, 2023 at 11:13 am

Magnificent goods from you, man. I've understand your stuff previous to and you are just extremely great. I really like what you have acquired here, really like what you are saying and the way in which you say it. You make it enjoyable and you still care for to keep it wise. I cant wait to read much more from you. This is really a tremendous site.

Binary optionJan 22, 2023 at 03:35 am

I blog frequently and I really thank you for your content. This great article has really peaked my interest. I will bookmark your blog and keep checking for new details about once a week. I subscribed to your Feed too.How to make money online? Copy successful trades of traders in copy binary options and copy crypto trading. From 100% to 1000% per month can reach your income.

18 wheeler settlementJan 21, 2023 at 07:26 am

%%

New honda Key FobJan 21, 2023 at 04:53 am

%%

Apuestas online casinoJan 20, 2023 at 04:59 am

If some one needs expert νiew rеgarding running a blog then i ѕuggest him/her to visit tһis webpage, Keep ᥙp the nice ԝork.

Mesothelioma AttorneyJan 19, 2023 at 15:06 pm

%%

Mesothelioma settlement NappaneeJan 18, 2023 at 00:37 am

Thankfulness to my father who shared with me about this blog, this webpage is truly awesome.

Mesothelioma LegalJan 17, 2023 at 22:06 pm

%%

Birth injury caseJan 17, 2023 at 15:33 pm

%%

Upvc Door HandlesJan 16, 2023 at 20:04 pm

%%

Online BettingOct 12, 2022 at 14:38 pm

Hi there, I enjoy reading all of your article post. I like to write a little comment to support you.

Buy-backlinks.rozblog.comOct 11, 2022 at 23:07 pm

Hey there just wanted to give you a quick heads up and let you know a few of the images aren't loading correctly. I'm not sure why but I think its a linking issue. I've tried it in two different web browsers and both show the same outcome.

Https://dentistcommunity.ir/Oct 07, 2022 at 04:31 am

Asking questions are in fact pleasant thing if you are not understanding anything entirely, but this post offers fastidious understanding yet.

BetturkeyOct 05, 2022 at 15:31 pm

This is very fascinating, You are an overly professional blogger. I have joined your rss feed and stay up for looking for more of your wonderful post. Additionally, I have shared your website in my social networks

別叫我奧古茲、奧斯曼、卡伊。 我是土耳其人,這個名字勝過任何頭銜。Oct 04, 2022 at 17:04 pm

I am really enjoying the theme/design of your website. Do you ever run into any internet browser compatibility problems? A handful of my blog visitors have complained about my website not operating correctly in Explorer but looks great in Firefox. Do you have any recommendations to help fix this problem?

Slot88topOct 02, 2022 at 21:13 pm

Hello everyone, it's my first go to see at this website, and paragraph is really fruitful in support of me, keep up posting these types of content.

FIFA World CupOct 02, 2022 at 20:14 pm

I love your blog.. very nice colors & theme. Did you make this website yourself or did you hire someone to do it for you? Plz respond as I'm looking to create my own blog and would like to find out where u got this from. kudos

สูตร บาคาร่าSep 29, 2022 at 23:28 pm

บาคาร่าสด สูตร บาคาร่า เป็นการถ่ายทอดสดมาจากสถานคาสิโนของจริง ตรงนี้ ได้กระทำการซื้อลิขสิทธิ์มาอย่างถูกต้องตามกฎหมาย และถ่ายทอดสดผ่านสัญญาณดาวเทียมไปสู่เว็บไซต์คาสิโนออนไลน์ เพื่อเล่นบาคาร่ากับเรา ทำให้ระบบเป็นการทำงานแบบ Real-time ไม่ใช่การเล่นผ่านโปรแกรม ทำให้ผู้เล่นเชื่อมั่นได้ว่า จะไม่ถูกโกง หรือเสียเปรียบสำหรับในการเล่นอย่างเด็ดขาด และที่สำคัญทำให้คุณรู้สึกราวกับได้เล่นอยู่ในบ่อนคาสิโนของจริงอีกด้วย สำหรับการเลือกเล่นบาคาร่านั้น ในขณะนี้ บาคาร่าหมายถึงบาคาร่าที่เหมาะสมที่สุดในประเทศไทย โดยได้รับการโหวตจากผู้เล่นจริง โดยเราค้ำประกันการได้เงินจริง จากการเล่นเกมกับเรา ที่มาพร้อมกับการดูแลเกี่ยวกับด้านความสะดวกทุกธุรกรรมการเงินของคุณ เมื่อทำฝาก-ถอน ตลอด 24 ชั่วโมง และก็ พนักงานที่มีหน้าที่สำหรับบริการลูกค้าตลอด 1 วันด้วย

کلاه کاسکتSep 28, 2022 at 16:06 pm

I enjoy what you guys are up too. Such clever work and exposure! Keep up the superb works guys I've added you guys to our blogroll.

Ammo for sale onlineSep 23, 2022 at 10:13 am

Generally I don't read article on blogs, but I wish to say that this write-up very pressured me to check out and do so! Your writing taste has been amazed me. Thank you, very great post.

Jasa Pasang ACPSep 22, 2022 at 03:25 am

Hey, I think your website might be having browser compatibility issues. When I look at your blog in Ie, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, awesome blog!

Can i get cheap cephalexin without prescriptionSep 21, 2022 at 19:03 pm

Outstanding story tһere. What occurred ɑfter? Good luck!

Game slot777 onlineSep 20, 2022 at 12:19 pm

I was able to find good info from your content.

Aluminium Composite PanelSep 19, 2022 at 18:47 pm

If you desire to improve your familiarity only keep visiting this site and be updated with the hottest news update posted here.

Methadone for dogs painSep 18, 2022 at 16:41 pm

We're a group of volunteers and starting a new scheme in our community. Your web site provided us with valuable information to work on. You've done a formidable job and our whole community will be grateful to you.

Https://khanegiland.com/Sep 16, 2022 at 11:39 am

I am now not sure where you're getting your info, but great topic. I needs to spend some time finding out much more or working out more. Thanks for great info I used to be looking for this info for my mission.

Sap b1 training ukAug 30, 2022 at 15:34 pm

However, each employer must verify that by asking questions you related to that ability.

Atlet angkat besiAug 24, 2022 at 14:14 pm

I constantly spent my half an hour to read this blog's articles everyday along with a mug of coffee.

GunishJul 18, 2021 at 08:37 am

Interesting perspective. I have one more insight. At some point one has to decide if this customer is adding value to your business or not. The hardest decision is to say no to a customer. Particularly one that has worked with you for many years. In my experience even more important than saying "yes" it is saying "no" to bad business. I have seen many a garment exporter go out of business trying to work with a buyer assuming the past equations will work - but the world keeps changing. Very good article Sanjay. these tips are practical and something that no MBA can ever teach you.

Satheeshkumar DJul 05, 2021 at 09:58 am

Sanjay Ji... Nice article. Keep writing.

Poonam Sood lalJul 04, 2021 at 18:27 pm

The hardest negotiations are the ones of a claim between a customer and a factory. Firstly you have to verify that the claim is correct and not made up. Then you have to convince the factory that there was a loss at the customer end and that if he wants to stay with long term business he must honour the loss. All this depends on your relationship as a buying agent between a customer and a factory. Over the years many errors have happened in the business. I’ve always told my team that if errors were not happening then we were not needed The first attempt is to see if the error can be corrected without the customer coming into the know If that Cant be done then the customer has to be taken into confidence and counter measures have to be taken Eg. when we were part of the retailer itself the solution found was to fast track alternate styles and let the planner put those on the floor When we were a buying house then you have to let the customer come up with the answer and you can only offer options if you feel you can’t solve the issue locally This is a really dynamic business and issues keep coming up and resolving them amicably is what keeps the customer with you Well written article on the whole

Poonam Sood lalJul 04, 2021 at 18:25 pm

The hardest negotiations are the ones of a claim between a customer and a factory. Firstly you have to verify that the claim is correct and not made up. Then you have to convince the factory that there was a loss at the customer end and that if he wants to stay with long term business he must honour the loss. All this depends on your relationship as a buying agent between a customer and a factory. Over the years many errors have happened in the business. I’ve always told my team that if errors were not happening then we were not needed The first attempt is to see if the error can be corrected without the customer coming into the know If that BBC ant be done then the customer has to be taken into confidence and counter measures have to be taken Eg. when we were part of the retailer itself the solution found was to fast track alternate styles and let the planner put those on the floor When we were a buying house then you have to let the customer come up with the answer and you can only offer options if you feel you can’t solve the issue locally This is a really dynamic business and issues keep coming up and resolving them amicably is what keeps the customer with you

Kamal sehgalJul 04, 2021 at 10:05 am

Wow , Very interesting article sanjay sir.

Prashanth HVJul 03, 2021 at 11:51 am

Well described the Rules Sanjay!