My Sourcing Journal #1

Over my many years in this industry, my journal has amassed quite a few pages which are about my day to day learnings at work.

These learnings today have become unique insights into this industry & its functioning.

When people asked me to write something about sourcing, I decided to peek into my journal and share a few of my insights.

A Vendor is one of the main stakeholders of our business, and hence my first blog in this series is about;

Selecting the Right Vendor

How important is it to select the right vendor? How often do we go with the vendors we are comfortable with? The ones, we know will offer us least resistance when we ask for last minute changes, bear with our slip ups and those who will cover for us during reviews.

So this brings us to the question,

How important is it to select the right vendor and how does one do it.

It’s important to stress the criticality to study the geographical spread of factories. For easy example, split the country into four zones, north, east, south, west. Identify key category hubs in each region and decide the percentage split in desired business from these hubs.

This decision can be based on cost, product handwriting, logistical ease, capacity, regional stability to name some.

It’s important to also de-risk the business by ensuring that each category is well balanced in capacity allocation. So if there are any major disturbances in a region, it does not impact the whole business and one can localise the impact.

Once done, then look at developing factories or placing business in these hubs. The same applies internationally as well; specialisation, cost, duties and lead times play a major role in the decision. It’s always good to revisit this regularly and set clear targets for de-risking and optimising before getting into vendor selection.

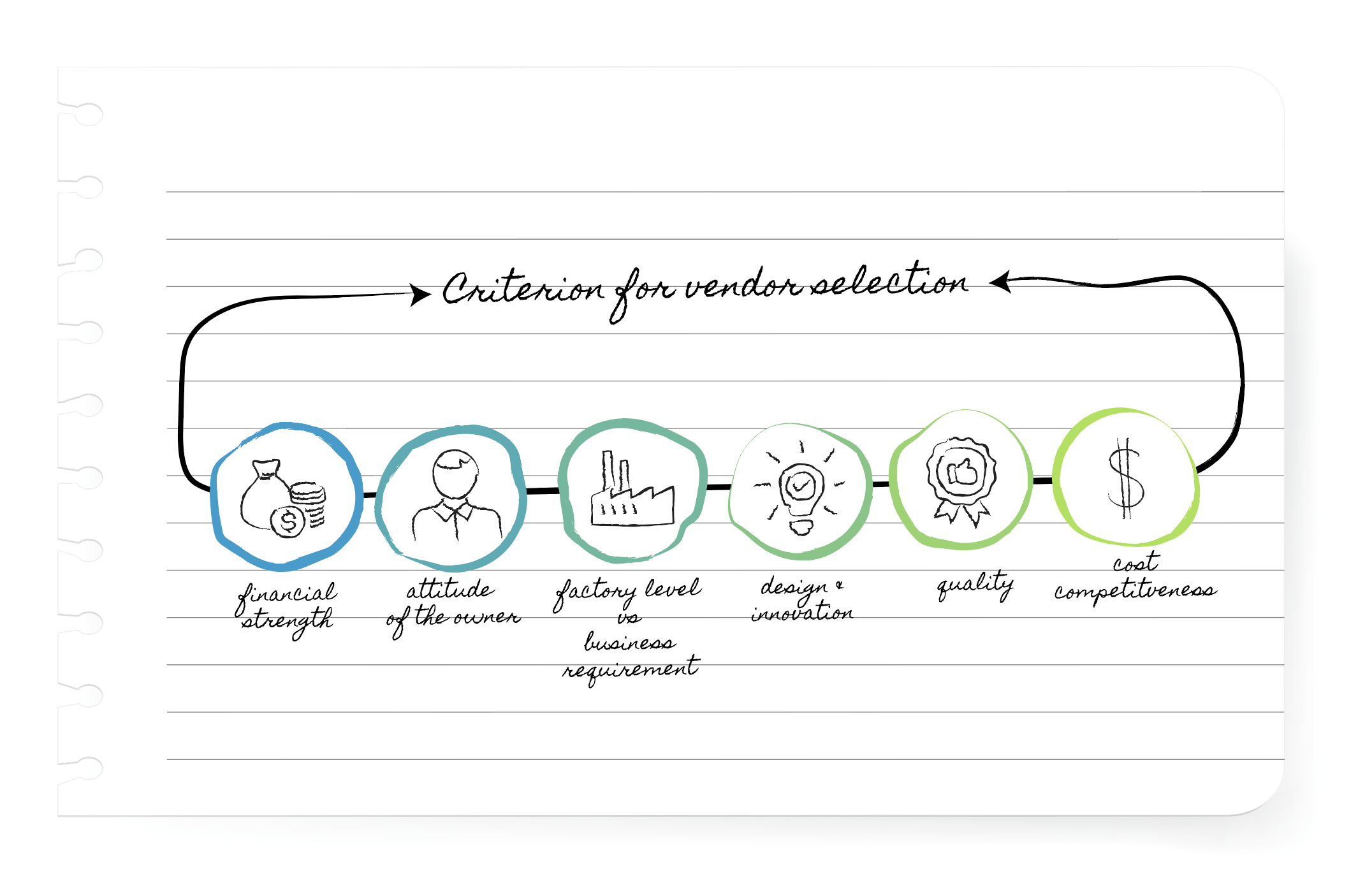

What should we look for in vendor selection

It’s always good to develop a points based vendor rating system. This allows for objective assessment and unbiased decision making. And these points should be from different stakeholders in the system, like finance, quality, compliance, sourcing and product/design teams.

Its good to even look at taking feedback from raw material vendors to understand the the culture of the vendor.

Having said this, let’s look at some of the criterion for vendor selection.

Financial Strength

The first question to ask is if the vendor has the financial capability to manage his working capital. The most critical point being, can he manage an additional month of working capital stress? It’s important that a month-wise investment plan is worked every season with the vendor before deciding volumes to be placed with him.

Attitude of the Owner

How is the vendor’s attitude towards business ethics? Is he too stuck up with his idea of working or is he open to new ways of doing business? Is he the kind of vendor one can build a long term commitment with? All businesses have ups and downs; can we count on the vendors support during such times.

Factory level versus the Business requirement

Is there possibility of growth? What kind of internal quality processes does the factory have? Is there some basic compliance in place? Is the factory capable of investing in ethical, sustainable business practices? Does the business have the capability of going online and digitally managing the business.

Design and Innovation

What kind of design and innovation support is the factory capable of giving? Is the factory investing in innovation and sampling? This becomes very important as we keep moving to value added products.

Cost Competitiveness

What is the cost structure of the factory? How has the factory invested in efficiency and cost management? How good is the factories own sourcing capability for raw materials? These continue to be one of the key driving factors.

Quality

Can the factory become a green channel quality resource in the next one year. Such factories should be prioritised over others. Ideally 30-40% factories should be green channel in the complete supply chain.

Having discussed the above, it would be important to understand the following aspects as well, like Management control of vendor base (defining an optimal span of control by number of vendors being managed) is important. As is keeping an ongoing vendor development plan to ensure that there are always new vendors being identified, assessed and kept ready for the future.

So finally we come to the benefits of having an objective approach to vendor selection.

Benefits

The benefits are many and just to enumerate a few.

And finally I cannot emphasise enough the importance of a seasonal audit for this and making this the key deciding factor in placing business. This will ensure that there is a seasonal review of vendor and will allow for the vendors at the bottom of the rating system to be either replaced or given a warning and pushed to improve.

A lot of people will say, what about other teams wanting their vendors or urgent requirements, when there are no capacities blocked. Well, if you are diligently following this way of working, it’s never going to be an issue. Just remember that as long as you clearly define a span of control, introducing a new vendor will mean taking another one out.

These were some simple pointers to creating a relevant and robust vendor base. What do you think? Please do share your thoughts in the comments section below.

I would like to thank Ms.Poonam Sood Lal for helping shape this article with her invaluable inputs.

RELATED TOPICS:#Apparel,Anindya Ray

Leave a comment

Our email address will not be published. Required fields are marked *

10 Comments

Raja ChidambaramDec 29, 2020 at 15:52 pm

Dear Anindya, Thanks for this article. I want to share something that came to me. I recently went through a program 'Become' conducted by Kaospilot, Denmark. they asked us to do An exercise of finding 'ideal collaborator characteristics'. This was a very interesting exercise where I looked at colleagues I have worked with as well as my clients and other collaborators. Very interestingly this led to looking at things that are tacit and not explicit. My list was: 1. Attitude of giving more than taking 2. Connectedness to a larger cause 3. Mutual respect and trust 4. Having deeper personal connect than just being a collaborator in a task 5. Wisdom and continuous quest for learning This list made sense to me because this is what I stand for. Hence I believe that alignment in terms of deeper principles and values are far more important in choosing any collaborator - be it a vendor or even customer!

R.P.SINGHDec 28, 2020 at 12:37 pm

dear anindya its always good to see your blog and like a lot... you always emphasis for the choice of right vendor, quality, innovation, compliance and prefer to choose the right vendor source.. but do you think that buyer is also coming back with proper support of regular flow of order, timely payment, fair price compare to market condition? i will say 'NO' because you already have lot of pressure to retain in market with your brand and look for brand growth or your employee's growth but never though how the Vendor is surviving ?? we also have the yearly wage increment pressure, increasing price of raw material, transportation etc , and additional to this you want to retain the same price.. Payment never come in time?? how do you want to grow without giving support to Vendor??

Rajat Kumar bhandaariDec 28, 2020 at 11:08 am

Very well explained and to the point... For me being an existing vendor this article is sort of a guideline as to what is expected from a vendor and how do I need to move forward in order to stay in the race....Thanks dada for enlightening me ....

Manoj Kumar M.RDec 27, 2020 at 11:27 am

A financially stable Vendor who has built the organisation with the importance of core elements People, Policies, Process & Product, with a Good Management. With the support of brands in providing business will definitely yield growth for the vendor & brands. Sir, It is a very good article, well explained on the Vendor Selection Criteria. Great learning ???

Ashish ChaturvediDec 26, 2020 at 13:24 pm

From someone who has worked with international and local brands both, there is a fundamental level of mentality that needs to be addressed when it comes to Indian brands. There is a sense of entitlement among sourcing executives where suppliers are just looked down upon. In case of international brands, suppliers are made to feel like partners. Most good manufacturers in India are wary of working with local brands exactly for this reason. Something for you to ponder about as well.

Prashanth HVDec 26, 2020 at 12:24 pm

Very well put Anindya. Agree with all the above points. To add few to them, the dependency of the vendor on the customer is also very important. What % of vendor's business is dependent on us. If the dependency is very low, then the mind share that vendor would give to a customer will not be high. As there is no mind share even the preference and priority will also reduce. I think this also one of the major parameter for vendor selection.

Neeraj KatochDec 26, 2020 at 11:56 am

In my experience there have been instances where all of the above criteria’s met of a vendor, but there was no willingness from one of the parties to collaborate; Reason was simply the uncertainty that could come with a new vendor. Most of us are always seeking to make partners with parties who we can trust upfront. What has been their history? What kind of service do they provide other customers? Are their payment cycles regular ? Do they have a good team who can cater to our requirements ? Do we have a strong referral point ? Will they stay loyal to all the commitments? So on & so forth. Hence the attitude of the owner plays a vital role. If the attitude is right there will be willingness to bend backwards too !!

Neeraj KatochDec 26, 2020 at 11:53 am

To get a right vendor onboard is like half the battle won. In my experience there have been instances where all of the above criteria’s met of a vendor, but there was no willingness from one of the parties to collaborate; Reason was simply the uncertainty that could come with a new vendor. Most of us are always seeking to make partners with parties who we can trust upfront. What has been their history? What kind of service do they provide other customers? Are their payment cycles regular ? Do they have a good team who can cater to our requirements ? Do we have a strong referral point ? Will they stay loyal to all the commitments? So on & so forth. Hence the attitude of the owner plays a vital role. If the attitude is right there will be willingness to bend backwards too !!

Paresh ShahDec 26, 2020 at 11:50 am

Well defined and easy to grasp criterion Sourcing and vendor selection is equally a common sense approach It is a relationship where vendor & brand OR retailer over the period supplement each other and become partners in progress A person with right attitude is the biggest and most imp deciding factor and I suppose such entity can always be cultivated to be a reliable & long term vendor - gradually other supporting pillars can always be created with intelligent nurturing and regular support Indian value system largely gives importance to an element of trust or BHAROSA & PURANA SAMBANDH which plays a big role in uninterrupted supply chain and it’s mutual India consumption story is real one and with very few factories with scale and understanding of the business brands need to create sustainable supply base to stay relevant and profitable

Sanjay LalDec 25, 2020 at 23:04 pm

Sourcing is a game of intelligence. It can break or make a retailer. And it is paramount for sourcing to develop a right vendor. Attitude of the vendor is most important. Half battle is won if attitude of the vendor is positive. Secondly it is vital for sourcing to exploit to strengths of the region and use them to maximum advantage. Sourcing should also learn not to put all eggs in one basket (region).