COGS! - The direct costs of producing the good sold by any company.

It is a term we are all familiar with. And the quest to REDUCE COGS is one of the key deliverables of any sourcing organisation. All companies look first at the sourcing function when it comes to reducing the COGS.

But the question I ask here is : Is it just the responsibility of the Sourcing function?

I believe it is the collaborative responsibility of different functions and they can empower the sourcing team to deliver better results. And hence I have taken up this topic as the fifth article in this series: My Sourcing Journal.

Here I will discuss in detail;

- Factors influencing COGS

- Sourcing controlled factors of COGS

- How design and buying teams can influence COGS

- Hidden costs which need attention

COGS may be a simple four letter term, but its impact on any business is considerably high. There are many different factors influencing costs and each needs to be looked at closely under a lens. It is an interplay of many different factors. Some of which are directly controlled by the sourcing team.

LET'S FIRST UNDERSTAND THE FACTORS THAT ARE CONTROLLED BY THE SOURCING FUNCTION DIRECTLY AND HOW THEY CAN ECONOMISE AND IMPACT THE COGS.

1. PLAY THE VOLUME GAME

Volume in business has a direct impact on costs of the products. Higher the volume, lower the costs.

Hence volume bundling has a big impact on the costs. This bundling can be done by consolidating orders across brands/sub-brands & business units. It helps in achieving scale in production and improving efficiency thereby lowering the costs.

Consolidating the vendor base within and across business units also helps in achieving scale as orders are not fragmented across too many vendors.

2. EVALUATING BEST PRICE

This involves granular cost-visibility through open-costing and internal standardisation of rate cards across processes and functions.

Cost transparency leads to an analytics driven best-price evaluation, which keeps the emotion and the comfort levels out of the negotiation and price evaluation. Today, we can also rely on digital tools and advance data analytics techniques to evaluate the costs.

Another aspect to consider here is establishing a competitive bidding process to get the best prices. This opens up the orders to multiple vendors and each compete to get the business in. Sometimes it makes sense to do this within the established vendor base, thus allowing processes and quality to remain untouched. But opens up the competitive spirit in vendors. However care must be taken to ensure that vendors do not cartelise to take prices up. Hence a hybrid between existing vendors and a few new ones is probably a good practice.

Nomination of yarns, fabrics and trims helps in further ensuring that costs are managed across the value chain and that we get benefits of scale through consolidation of raw materials across the vendor base.

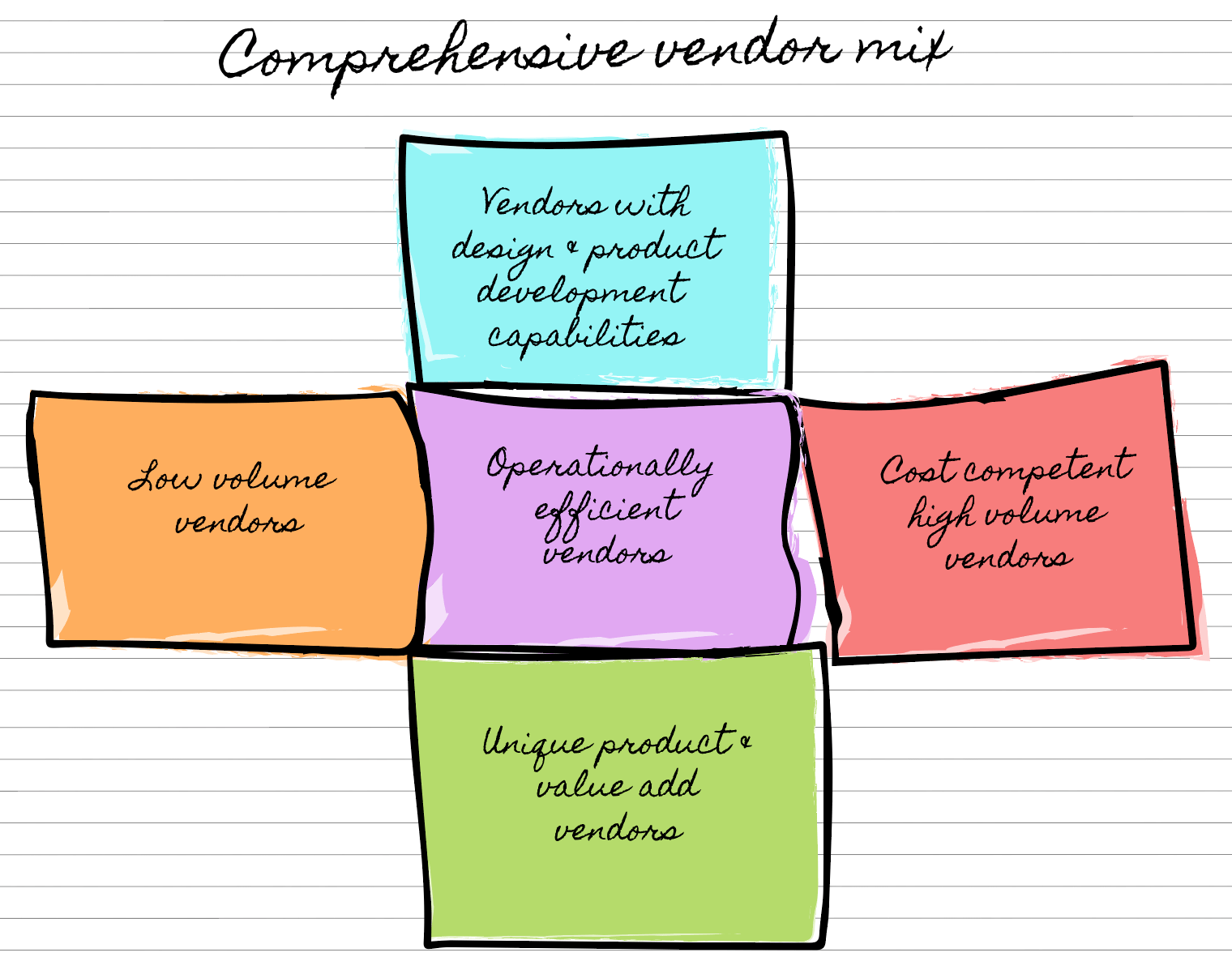

3. CREATE A COMPREHENSIVE VENDOR MIX

Each vendor has different strengths and weaknesses. Some may have design capabilities but higher costs and others may have exceptional operational efficiency but provide no market intel.

The vendors strengths should be assessed and a comprehensive vendor mix should be created based on the need of the business and what the vendor is bringing to the table, not necessarily only on cost.

The order allocation and bidding should be done based on these vendor capabilities. For eg. core products could be allocated to low cost vendors, while a product with special features should be given to a vendor specialising in the same, irrespective of cost competitiveness.

Another aspect to be looked into is to ensure regional diversity of the vendor base. A regionally diverse vendor base gives an organisation a competitive advantage. While it safeguards them against many issues (refer to previous article) , it also creates a unique competitive environment and helps to play on the regions strengths.

Ensuring an optimal distribution across sourcing hubs with diverse offerings is very important. One region may have advantages which the other region lacks, and this advantage is passed on to the brands in the form of costs.

Undeniably the sourcing team plays a major role in determining the COGS in a business.

But is it the only function responsible for reducing and optimising it?

The answer is no!

There are other factors which play an equally important role but outside the purview of the sourcing team. This is where the Design and Buying teams step in.

The designers and buyers are the foundation of any apparel business. Many factors when controlled at the conception stage can economise the costs. These are directly influenced by the design and buying teams.

FACTORS INFLUENCED BY THE BUYING AND DESIGN TEAMS AND HOW THEY IMPACT COGS

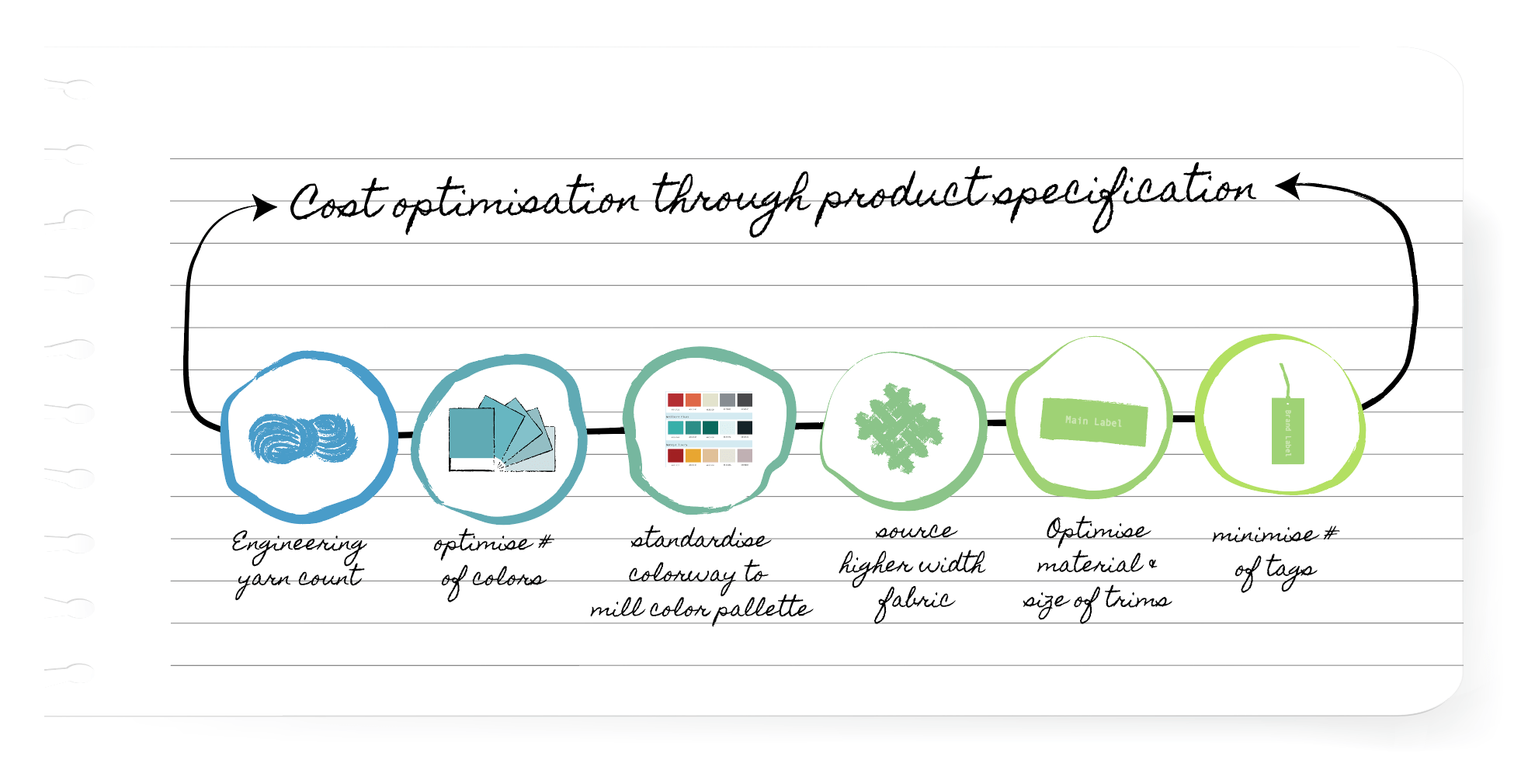

4. PRODUCT SPECIFICATION

Product specification comes from the designer and building a design led cost control mechanism helps in reducing COGS effectively.

Small shifts in design process as demonstrated in below infographic have a big impact on the costs.

Standardising product components like fabrics, trims, tags etc further adds to it.

Clubbed with optimised buying depths through regulation controlled design width based on analytics, these help in building scale and achieving component as well as garment MOQ’s. Thereby reducing COGS.

5. PLANNING & PROCESS IMPROVEMENT

Due to the seasonal nature of the apparel industry, manufacturing capacity is under-utilised during lean periods. The buying teams can use this to their advantage and plan production of core/all year round products at this time. The vendors usually give lower costs to keep their production capacities occupied.

Another important aspect in planning is fabric platforming and forward buying. Based on historical data and trend analysis, the buyers can book griege fabrics, core fabrics, yarns etc which offsets increase in raw material prices. A low hanging fruit is to take advantage of platforming across departments, standardising a certain minimum percentage of designs through platformed bases.

Sampling cost is an oft neglected one which is built into the final COGS. Utilising technology and shifting to digital sampling and prototyping also reduces number of iterations, costs along with building other efficiencies into the process.

6. RELATIONSHIP RESTRUCTURING

Along-with diversity of vendors, it is also important to optimise the buy model itself. How much are buying through agents, how much direct FOB, how much imports, how much specialised vendors for value added products? This has a direct impact of cost, quality and delivery effectiveness.

All these factors, whether controlled by sourcing or influenced by the design and buying teams are not mutually exclusive.

They are interdependent and it's a collaborative interplay that is required to impact COGS. A responsibility to be borne by all the three functions. If platforming and cost optimisation is done at the design stage itself then leveraging them becomes easier and benefits the business overall.

Any organisation which is looking to impact COGS has to develop a strategic sourcing plan based on the above factors.

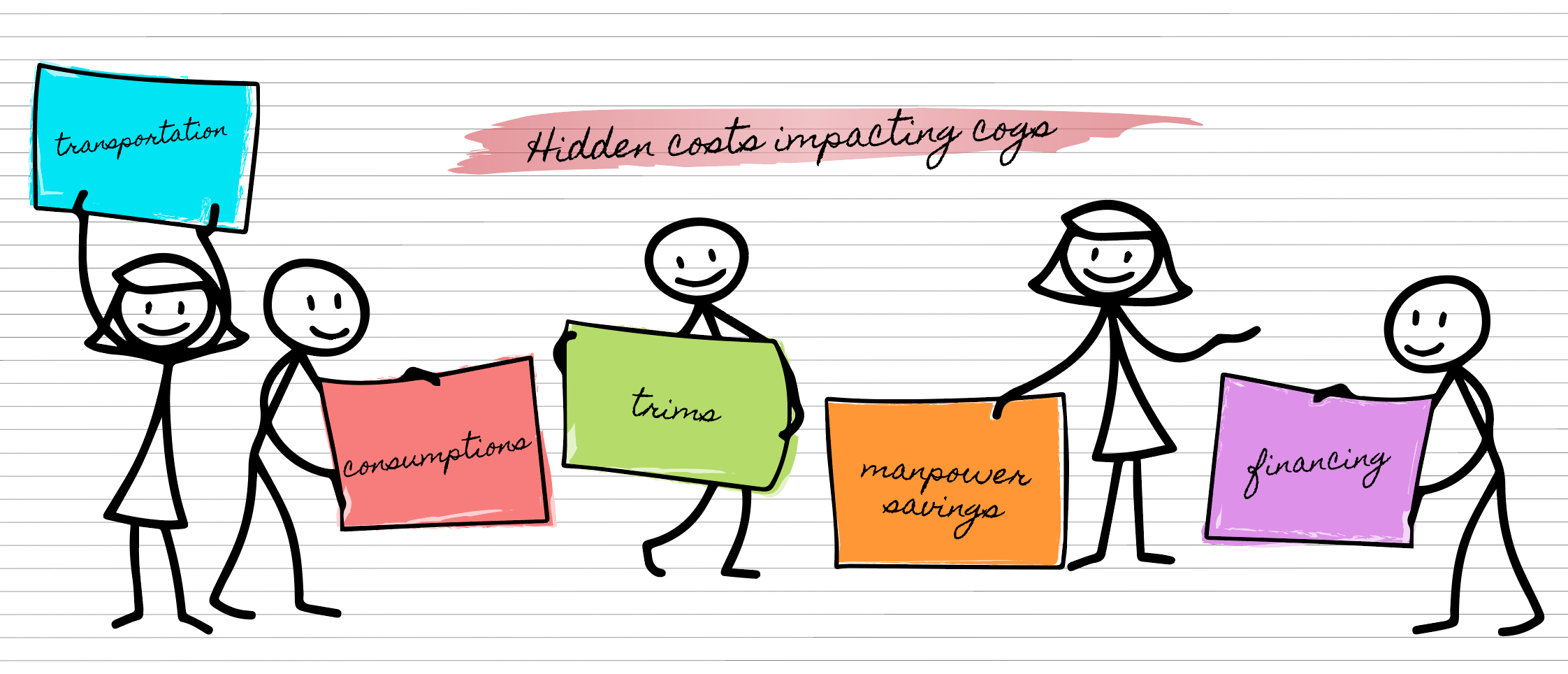

The factors charted above are some of the big ticket items, strategising which will have an immediate impact on the COGS. But what one overlooks are the hidden costs. These may appear to be of lesser consequence, but further examination shows that they do have a substantial cumulative impact.

WHICH ARE THESE HIDDEN COSTS?

TRANSPORTATION

Managing inwards logistics through strategic third part tie ups may prove efficient and cost effective as against fragmented vendor managed deliveries.

CONSUMPTIONS

Standardising fits and specs across brands and sub brands has an impact on reducing the COGS as well as improved consumer experience. Having a technical team with CAD’s to back up consumptions and resolve disputes scientifically helps.

TRIMS

Trims account for 12-15% of the costs and yet this is an area which is often ignored. We over engineer these at product level but they have no actual relevance to the end consumer; often landing in garbage bins.

Questioning the purpose of each trim and eliminating the unnecessary ones is a way to reduce costs. Also, harmonising trim specs across brands and sub brands helps in bringing down the costs.

MANPOWER SAVINGS

This is an oft ignored area, as it does not impact COGS directly. But creating GREEN CHANNEL factories reduces manpower requirement. Also increasing the scope field quality team to do factory follow ups and reporting can ease out a lot of the manpower required for follow ups at the office. These also reduce travel costs.

FINANCING

All businesses need money to function. This is most often borrowed money which attracts costs such as interest etc. This again is an ignored area that affects COGS. Even costs such as raw material holding, warehousing etc. have impact. Assessing the vendors financial strength and costs he incurs in such places is also of significant importance.

Reducing COGS is not an elusive dream, it is easy to execute. One must look at each and every factor that influences COGS and assess them minutely and derive business relevant strategies for their organisations. There are simple rules, clear accountability and some out of the box thinking that is what’s required.

And lastly it a collaborative effort which needs focus from multiple functions.

There is no right or wrong way to do this. Different business models should focus on different aspects of this & develop a tailored strategy.

I am sure you all have had a brush with this subject. What do you think? Do leave your comments about the subject.

RELATED TOPICS:#Apparel,Anindya Ray

Leave a comment

Our email address will not be published. Required fields are marked *

8 Comments

PApLuJdAlDec 12, 2023 at 18:41 pm

sildenafil vs viagra s been in during his checkered NBA career

Sairam SharmaMay 17, 2021 at 16:19 pm

Sir, very well articulated and thanks for sharing insights on COGS. As part of support to the sourcing teams in defining cost accuracy can be done by partnering with the industrial engineering teams. The IE teams can assess, evaluate and provide indepth analysis on the entire cost structure of an production unit like cost per minute and efficiencies which the production unit generally work on. This will help the sourcing teams decide and select on the production unit as well as on the product capability front of the production unit / business partners. An other theory to establish with the design teams while working on COGS is to have a consolidated COGS % for the season. This will help sourcing teams to average out the costs on a overall product basket.

Gunish JainMay 16, 2021 at 11:58 am

Very detailed article. Great ideas! Would like to add another element - the sourcing process. Very often we build processes - which are checks and balances, without realising the implication it has on long term costs. I have often used this example - imaging if you had a vendor base where for all styles, no fit approval process was required. How much saving does it give you in terms of cost and lead time. Investing in improving vendor factory processes and working with building factories with greater capabilities really helps in reducing overall costs. So, taking up pilot projects with vendors really helps. The Quality team should be focused on this.

Ravindran R SMay 16, 2021 at 10:30 am

Thought full article , thr framework designed definitely guide to all professionals in sourcing functions.

Ramesh.GMay 15, 2021 at 20:48 pm

Dear Anindya, Thanks for sharing such a wonderful article on cogs. In a nutshell one liner we can say “ design your product for delivery” It will ensure to cover all the aspects of working across every functions stated and ensure them to understand all of them are service providers to consumers and the profit and the monitory benefits of individuals is the by product of following the above mantra rightly And bringing balance and equal weightage on Cogs for every function from d 2 d ( design to delivery)

Senthil kumarMay 15, 2021 at 15:11 pm

Value for money is each and every customer is looking for in all they buy, be it a product or a service. If we can crack this then the product/service wins the customer. A relevant topic at these testing times. Thanks for brushing up the importance of COGS.

Yogesh ShettyMay 15, 2021 at 15:01 pm

So well written.Anandiya you have covered all aspects wherein one could look into their costing of their products and services.Hope most of our industry friends read this article and follow most of the points highlihted by you.

Prashanth HVMay 15, 2021 at 10:08 am

Great you picked this topic Anindya. At the present scenario where the raw material prices are increasing, there is a huge pressure on sourcing to keep the cost unchanged, which is impractical. As you have rightly pointed out COGS is a team effort of Design, Buying and sourcing. All 3 departments has work in tandem to achieve the required costs.