Quality 4.0 - Not just technology Part 1

The word “QUALITY” is one of high significance in our industry.

It is defined as; “the standard of something as measured against other things of a similar kind; the degree of excellence of something.”

Though the word is defined as above, people usually use it as a synonym for “good”. Many bands tout their products as “High Quality” or “Superior Quality” without really defining what the characteristics of quality are.

Quality is a question of trust. Reputation is built on this trust & it is a hard earned characteristic, one which shouldn’t be squandered with. We must celebrate the role that everyone in an organisation plays in building and sustaining quality: customers, suppliers, staff, regulators, shareholders and society. Hardly a day goes by without hearing about quality failure and its impact on the customers and organisations alike. In fact, the importance of quality well recognised around the world.

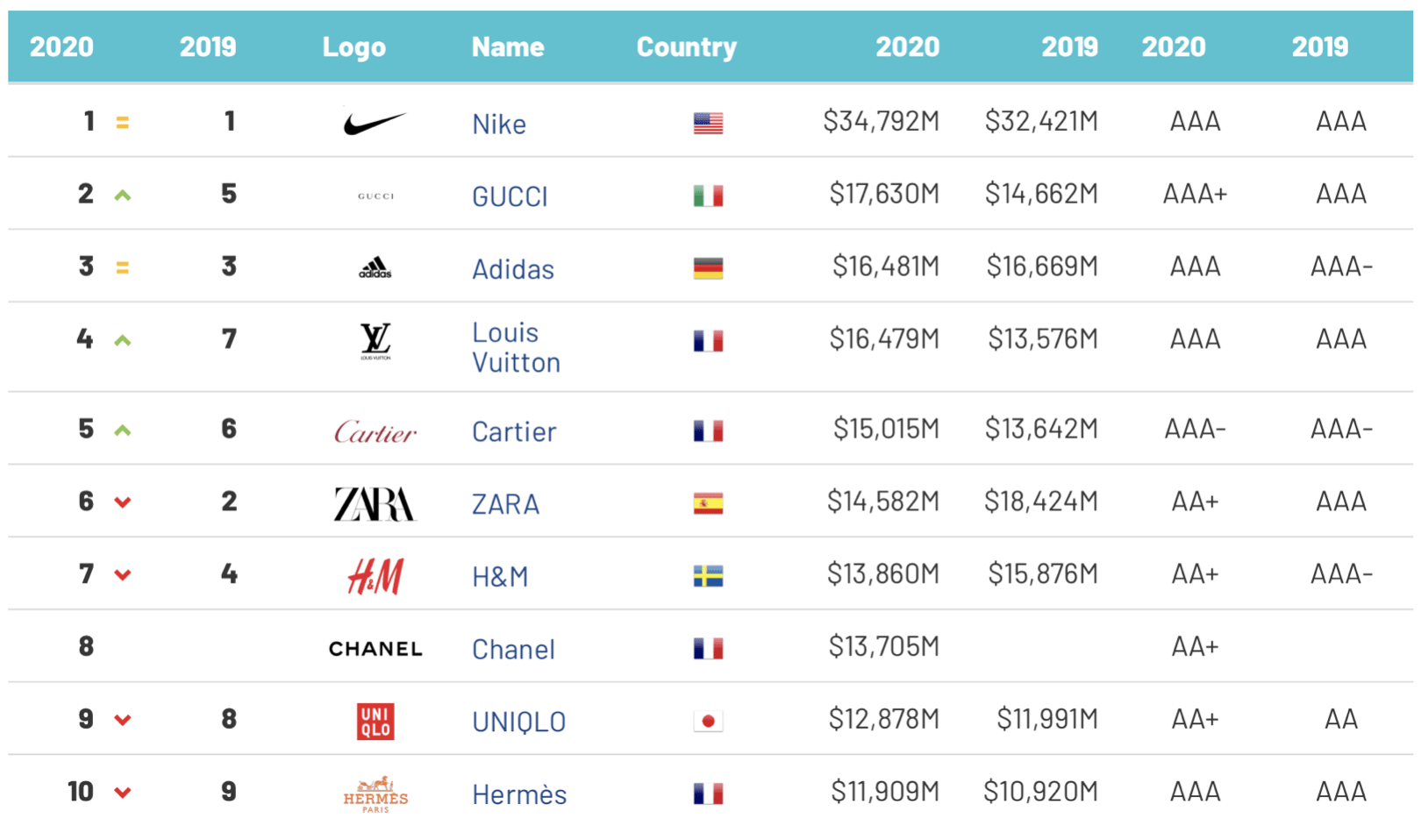

As per the recent Apparel 50 2020 ranking, the top 10 Apparel brands have a AA+ and above quality rating. Perhaps its the reason for their sales too.

Data Resource : https://brandirectory.com/rankings/apparel/table

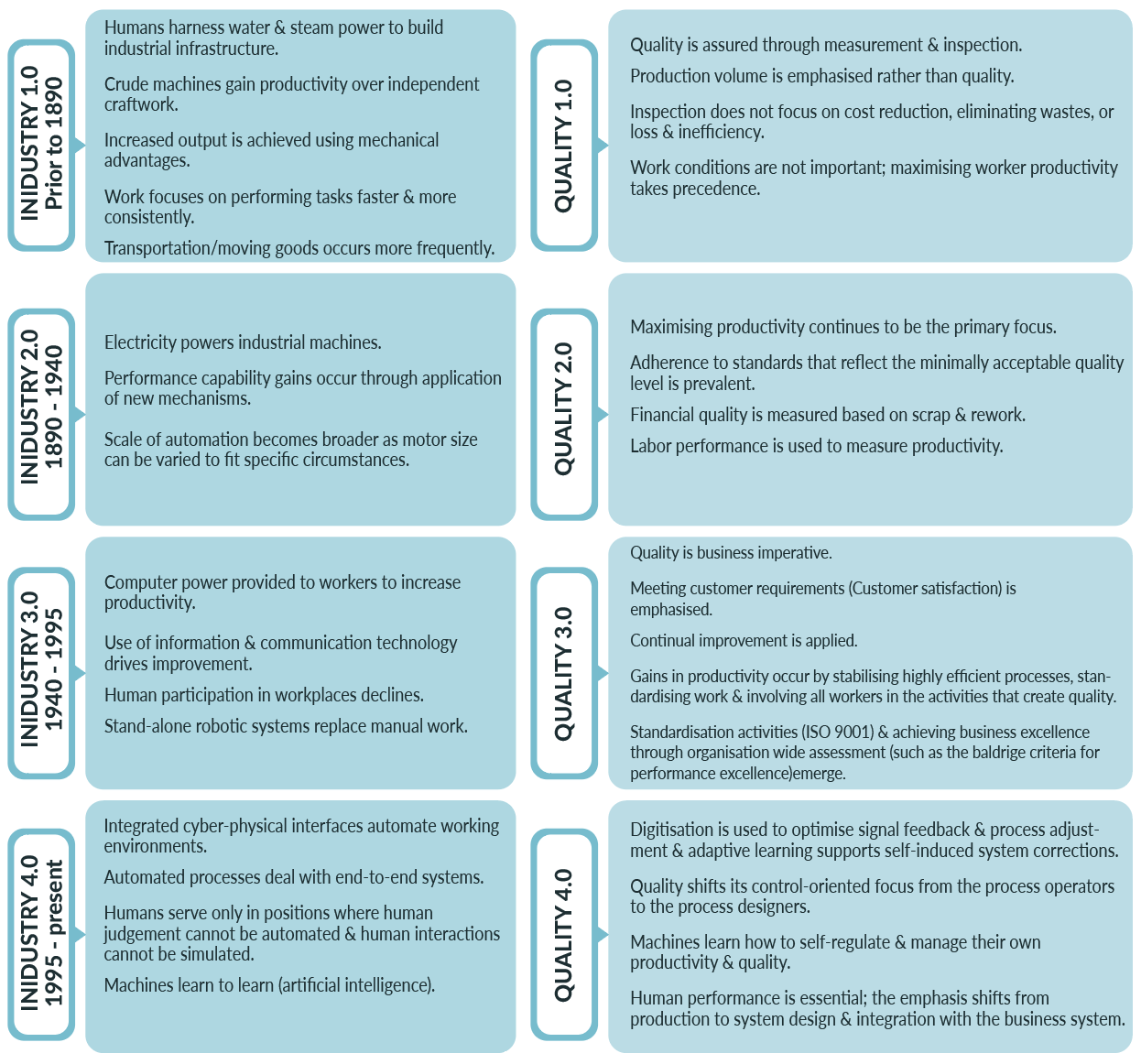

THE EVOLUTION OF QUALITY 4.0

During the first industrial revolution (late 1700s and early 1800s), innovations in steam and water power made it possible for production facilities to scale up and expand potential production locations. Before then, manufacturing facilities had to be constructed along rivers so waterwheels could be used to generate power.

By the late 1800s, the discovery of electricity and development of infrastructure enabled engineers to build machinery for mass production. Iron ore production increased, enabling machines themselves to be mass produced. In the United States, the expansion of railways made it easier to obtain supplies and deliver finished goods.

Evolution of Quality from Controlling to prevention

If you review the history of quality in business, you will find that the idea of ‘controlling’ quality emerged in the first decades of the twentieth century. Yet, even at that time, the concept was beginning to expand from the then-prevailing practice of after-the-fact inspection to the more proactively-minded prevention.

What it Means in Current Generation ?

Quality 4.0 represents an opportunity to utilise those Industry 4.0 technologies to realign quality functions with broader organisational strategy. It provides the scope to both redirect quality activities and to alter the perception of the quality function in organisations as being little more than the “quality police.”

For many organisations, these stem from inefficiencies resulting from issues such as lack of cross-functional ownership, ineffective communication, and fragmented traditional quality systems.

Quality 4.0 presents an opportunity for organisations to review the root causes of current barriers to quality success, and engage in strategic planning to explore how new technologies and the advantages they deliver – such as improved data transparency and high quality data-driven insights – can be leveraged to achieve a culture of excellence

Let’s look into a case study which I thought would be more relevant to this topic and well explained as to how Industry and Quality perceive together. This case study will reveal the significance of quality 4.0.

In 2018, Boston Consulting Group (BCG) invited ASQ to partner in a study exploring Quality 4.0, focused primarily on the manufacturing sector in the U.S. and Germany. The study sought professionals’ perceptions of skills needed to implement Quality 4.0, obstacles to implementing, and cases for the use of digital quality management. Click the link below to read the complete case study

https://www.bcg.com/publications/2019/quality-4.0-takes-more-than-technology

Based on the study four key themes come to the front :

- Manufacturing and R&D as the areas that will benefit most from improved quality. The perceived importance to manufacturing reflects the visibility of value created on the shop floor. Quality is neither the process nor the output, but everything—how we conceive, design and specify the product, how we procure its materials and components, how we manufacture it, market and distribute it.

- Successful implementation will entail improving data quality and management as well as analytics technologies and methodologies. Technological advancements in fields such as data, analytics, collaboration, scalability and connectivity are driving not just innovation, but true paradigm shifts in manufacturing and the delivery of products and services

- Adoption : Nearly two-thirds of survey participants believe that Quality 4.0 will significantly affect their operations within five years. Most companies believe that, within the quality function, digital technologies will be important for quality governance, performance management, and training.

- Implementation : We can confront that 16% say that their company has started to implement Quality 4.0 ; only 20% say that their company has started to plan for implementation, and 63% have not even reached the planning stage yet.

Traditional Quality Management Challenges

Customer needs are ever-changing, which makes it difficult to maintain a high level of quality. In addition, product recalls cost organisations millions of dollars and loss of goodwill and reputation. Employee efforts must also match demand and customer expectations. Further, resources must be allocated for research and innovations in order to develop new methods of quality. Also, global standardisation of quality standards is difficult when companies are producing from different locations. Finally, it is difficult to sustain quality levels as products become more customised.

CONCLUSION

Quality 4.0 in no way diminishes the role of people in assuring quality. Indeed, giving people the skills to apply digital tools and to tell data-driven stories will be an essential part of ensuring quality in the factory of the future. Across manufacturing industries, the companies that win in the 2020s will be those that use digital to redefine the meaning of quality excellence.

The Insights of the growing Apparel Quality will be taken up in Part 2.

RELATED TOPICS:#Sourcing,Textiles,Apparel,Quality,Supply Chain,manufacturing,technology,textile industry,supply chain strategy,apparel industry,Sourcing Strategy,quality4.0,industrial revolution,compliance,high quality,superior quality,Ajay Ravuri

Leave a comment

Our email address will not be published. Required fields are marked *

6 Comments

Cialis online no prescriptionSep 22, 2022 at 12:18 pm

Nice post. I was checking continuously this blog and I'm impressed! Extremely useful information particularly the remaining part : ) I handle such information a lot. I was seeking this particular information for a very lengthy time. Thank you and good luck.

Kumara H KJul 30, 2020 at 20:35 pm

Hi Ajay, Quality is plays a major role if any brands to be succeed and in top 10. well explained that how industry and quality perceive together. Quality 4.0. has significant potential to change whole manufacturing processes and business models.Apparel industry need to invest in technologies to start the transition from ordinary plant to the smart factory to gain competitive advantage.

MahamudJul 28, 2020 at 10:06 am

Sir, I understand little quality 4.0 after studying will be better. Quality 4.0 is among the many developments that are giving rise to the “factory of the future,” in which digitally enhanced plant structures and processes increase productivity and flexibility in the factory and throughout the supply chain. Digital technologies can help improve quality in various ways. For example, companies can monitor processes and collect data in real time and apply analytics to predict quality issues and maintenance needs. Digital tools also enable people to do their jobs faster, better, and at reduced cost.

Arun SJul 28, 2020 at 08:18 am

Hi Ajay, I believe always, Quality stands as backbone to any brands in their success stories, Well said, now in current generation all organization should adapt technologies, digital data transformation and need to review the outcome and root cause of barriers on a real time basis. Culture of excellence need to be build only if the organization updates technology based on current generation.

Ravindra ChawlaJul 26, 2020 at 18:59 pm

Hi Ajay...Quality is always my favourite subject and you have defined it very well saying that Quality is a question of TRUST. Data provided by you in the form of tables and gif's are really interesting and informative. I really wish that some of ALBL brands should also gets highlighted into top rankings. The insight take away from Quality 4.0 is changing to digital platform is must and inevitable to redefine the meaning of quality excellence.

AjayJul 28, 2020 at 14:33 pm

Thanks for commenting