What’s happening?

Day by day the input costs of textile/apparel ecosystems are increasing whereas the buyers/ consumers are expecting to get the merchandise cheaper and cheaper than what is being sourced before. Vendors cannot continue to reduce the prices for the sake of getting orders. If they do so their existence will be in jeopardy. Similarly, they cannot continue to demand an increase in prices from customers by stating the reality of the increase of raw material & other variable input costs. This will also lead to a break in the business chain & collapse the modality of the business at all ends.

Expectation

While we wish or continue to expect things to get better sooner or later, look forward to that kind of scenario happening at the earliest, is it possible to pause the business till then? We all know the answer to this. It’s our responsibility to find ways to manage the scenario at its best & continue to move forward to sustain.

Reality

Everyone is happy to look for a better tomorrow but, it does not come easily most of the time. It applies well for our industry as we have seen several challenges in the past, a recent example being the yarn price increase. We continue to hear the situation will stabilize in the future, but months are passing & the situation seems to be getting worse than before.

One thing we are sure of is, that challenges are going to increase day by day. Everyone will be pushed to the extreme in terms of prices & deliverables without compromising on quality & product outcomes. Yet we have to find ways to become successful.

So how can businesses tackle this and become successful?

One of the solutions for this is;

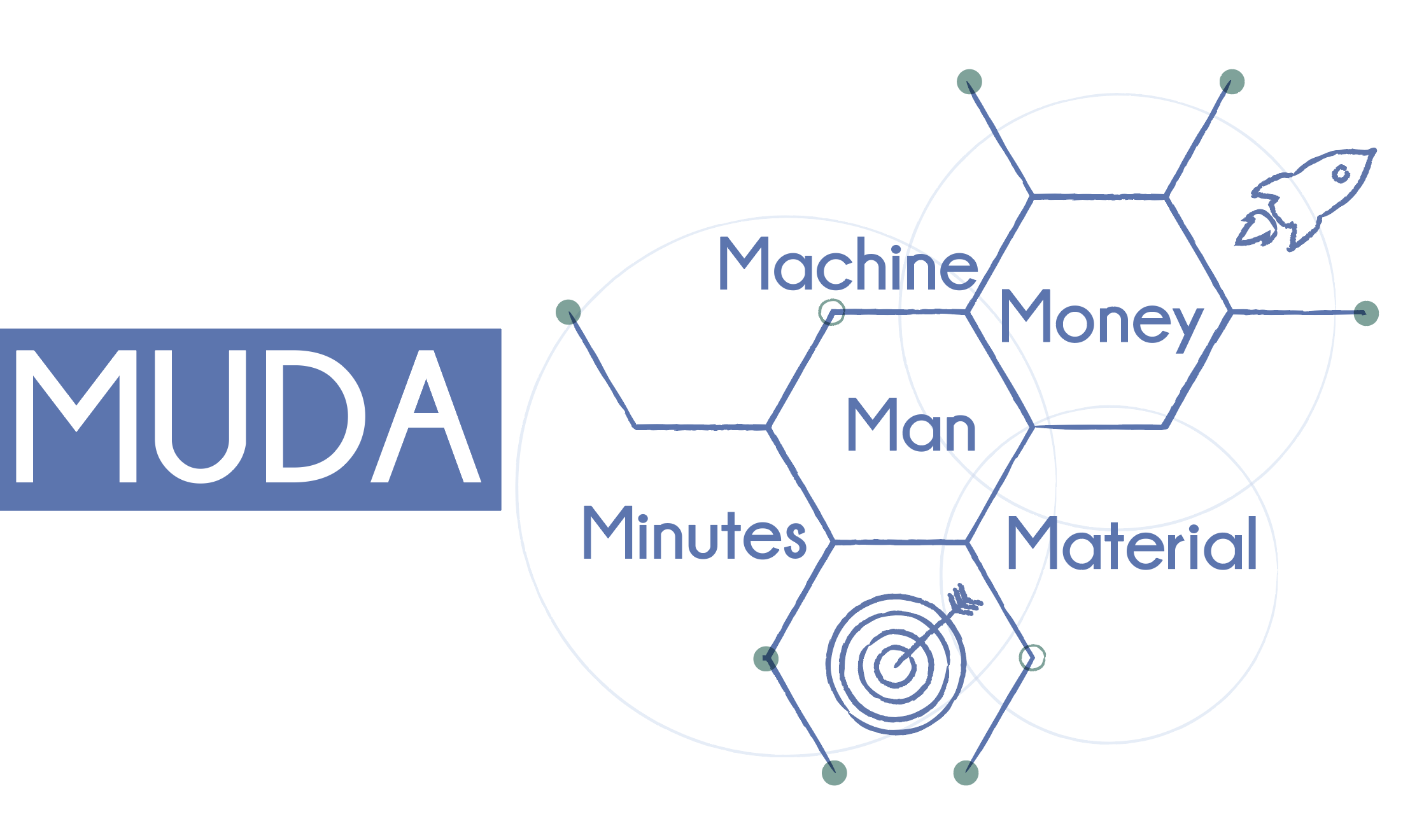

“Muda”

Many of you must know or have heard about this word - which means waste in the Japanese language. It’s a key concept in lean process thinking.

Waste reduction is an effective way to increase profitability. Here we are not talking only about the textile waste which gets generated while manufacturing, or waste that is discarded after primary use or is worthless, defective, and of no use.

In simple words “something which is not effective or unnecessary or not adding value to requirement those are considered as waste here & we need to control the spending towards such wastes.

It can be viewed based on the 5M principle –

1) Men 2) Machine 3) Material 4)Minutes & 5)Money

Men

The right personnel for the right position is a sure bet for any business to achieve effectiveness & efficiency.

Businesses often underutilize the skills of their people & unused skills of people are part of resource waste. Everyone should make a conscious effort to make this never happen so that it can yield benefits to businesses. Usually, companies are very particular & good at focusing on people who are not effective & not living up to the expectations of modern-day challenges, not able to cope up with business needs that have been identified & terminated. In my view more than this, companies should focus more on underutilization skills so that they can get better benefits out of them.

Right people make sure machines, materials, minutes, and money are utilized productively to achieve the goals or aims of organizations.

Machine

The movement of machines more than required to perform the processing will create a cost impact in a big way. Idle or broken machinery, empty facilities, taking too long for set up, not working according to the best of standards as such is adding woes to manufacturing in all aspects. In such cases, effective machinery management with the help of identifying MUDA on the given resources will help for greater effectiveness.

Material

Higher Inventory, overproduction with low quality, over-engineering of product in the name of creation which results in material consumption than what is required, will lead to waste & affects the businesses in a big way. So, keeping a close eye on this and managing it rightly thereby reducing the waste on the material front will give sizable savings. Thus, right thinking and right planning keeping MUDA in mind at an organization level favor them in a big way to manage businesses successfully.

Minutes

Time management is one contemporary aspect of business that has been employed in use by effective and successful business ventures to optimize delivery. We all know about time-wasters & how do we manage time well. The same was discussed in detail in my previous article TIME - THE TREASURE. When we identify MUDA we all know TIME IS MONEY. It is easier to capitalize the benefit on the same.

Money

Money, when properly organized has been the most known factor involved in the success of the enterprise in history. The quantity & quality of money expended in ventures has a direct bearing on the fruitfulness of the same over time.

Example:-

Anything said without a simple example can lead to a different understanding. I am quoting an example from my work experience. It’s about a company that has gone from a basic fabric vendor to one of the leading textile mills (industry pioneers). The man behind this success built this empire with his way of MUDA management and today he & his company is leading example like any other famous textile mills of our industry.

Yes, you have guessed it right, here I am talking about MR. Alagarasan- MD of Arthanari Loom Centre, Salem.

We all know Coimbatore is called Manchester of South India, due to extensive textile industry. In a similar context, it is wise to call ALC a yarn-dyed fabric Manchester of (South)India. As they are one of the most famous & preferable yarn-dyed woven vendor partners for many buyers across the globe. You name any buyer they would have worked with or shown keen interest to work with them due to their consistency across all aspects of the business. I have seen the effective way of MUDA identification & management by them which is one of the key reasons behind their success even at challenging times always (including recent pandemic). Let’s see few glimpses on how they managed MUDA in favor of their success with the 5M principle.

Man- they have used the skills of potential people with the right personnel for the right position approach. One of the examples is Mr.Ramesh Kumar @ ALC.

Machine- they converted rapier looms to use for making desk looms in blanket route to get consistency in bulk easily. Usually, people discard the machinery in their godown or sell them at lower price points. Here the MUDA is managed effectively.

Material- use bulk baby cones returned from their weaving section to make desk looms thereby reducing the development costs as well the same help them in enable to get the bulk fabrics right with set dye recipe.

Minutes- they have adopted an effective final fabric inspection method that defines, tracks the TAT & the best results on inspection quality & quantity. This gives a cutting edge over others to MUDA.

Money- Usually in libraries the power is always on to identify & make selections. They have adapted a method of artificial intelligence after few minutes if there is no presence of people the power is turned off and when people enter immediately it turns on. This is one classic example of MUDA.

Bottom line:

Successful management means identifying Muda and putting control measures thereby making optimal and responsible use of men, machines, material, minutes & money for the advancement.

Hope you like the concept of MUDA & its effective way to profitability even at challenging times. I have shared my views based on my experience & I have quoted an example from a known vendor partner to make things easier & simpler to understand & emphasize the concept of MUDA to everyone.

I am sure you have plenty of views to share & quote relevant examples from your end too so that people of the textile/apparel industry get benefits of the same with real-time experience at these challenging times.

RELATED TOPICS:#Apparel,Ramesh Gunasekaran

Leave a comment

Our email address will not be published. Required fields are marked *

14 Comments

CleatteJul 14, 2023 at 14:38 pm

cialis 5mg best price Mainly thats the only thing that has held me back from starting my own family

Buying cialis online reviewsOct 19, 2022 at 12:01 pm

I simply couldn't leave your site before suggesting that I extremely enjoyed the standard info a person supply on your visitors? Is gonna be again regularly to investigate cross-check new posts

Loganayagam. SMar 18, 2021 at 21:06 pm

Dear Ramesh G Congratulation to exptessed what we all thinking for current SURVIVAL.MUDA can practically & Religiously be incorporated in the bigger / lower set up organisation's & will be a little hardest task for the medium capacity sectors.proper poaching required in particular"M"s in which the management may not used to be... Anyhave your attempt has created an awareness to all to wake up atleast from now onwards...Infact to be continued as a part in our industry.

Vadapalli MohanMar 14, 2021 at 19:38 pm

In the current challenging times, need to implement MUDA for better efficiencies.

Shilpa SMar 14, 2021 at 17:50 pm

Best article ever sir its very useful article which motivates young ppl like us...Thank you for the very resources full article...share to all of us...

AnbazhaganMar 14, 2021 at 13:58 pm

This is one of the best article you have posted recently, Extraordinary simple article with clear live examples always simulates many people like us to think differently.

Venkatesh KumarMar 14, 2021 at 13:58 pm

Good one Ramesh. Optimum utilization of resources will be the USP of any industry to grow consistently and to counter the challenges which keep on coming every now and then in different dimensions. Technology upgradation is the another prime key to face demands which keep on happening in especially in our fashion industry. It is right time to focus on regenerated yarn thus we can balance virgin cotton prices volatility. Even global warming could be addressed largly with our waste to regenerated yarn from all form of wastes in textile industry and wasted pet bottles and its similar kinds to support our eco system.

Baskaran DevanesanMar 14, 2021 at 13:03 pm

Dear Ramesha Congratulations Well narrated and timely published article. This is an article gives an insight about MUDA and its application to face the crisis of yarn price . Keep writing to enlighten apparel and textile business. Best wishes

ArvindMar 14, 2021 at 11:49 am

Very true and more so in these difficult times !! Effective implementation will surely help to sustain irrespective of the size of the company ..very well written ramesh !

Ankita LashkeryMar 14, 2021 at 11:26 am

Hi Ramesh sir Your articles always helps us in some or other way. Thank you Ankita

SenthilkumarMar 14, 2021 at 11:09 am

Mr. Ramesh has given best sourcing knowledge of textiles curry and future.

Sandeep golamMar 14, 2021 at 11:02 am

MUDA , is surely a goods concept , but i guess shud be applied across the entire supply n sales chain , at every point if the fine tuning is done , it will allow the possibilty for every partner to breathe a little. with the yarn prices going crazy , fabric prices have gone insane , meeting targets is an issue , while the factory is not increasing its CM+WASH costs . increasing raw material prices was the last thing required after the markets are just opening up. every channel partner maker n the brand needs to use the sharpner to create a winning combo , while hoping that the fabric prices settle down back to normal levels real soon. like always all the best.

VISHAL GANERIWALMar 14, 2021 at 10:39 am

Hi Ramesh A must know and practice principles i these rather challenging business times. Thanks for reminding us.

Vijaya KrishnanMar 13, 2021 at 10:58 am

Excellent formulation Ramesh. Very true and the given example is very good. ALC is true pioneer who brought in know how of doing Mill made fabrics in South India. They have strengthened their infra where and when required. Right from etp, lab ,Indigo , heat setting etc.. But on the other side, I feel Alc is choosy on buyers and would always prefer to work with good payers. Though it is safe for the business they need to think about balancing of sharp priced volume business and luxurious value added business. Good one..keep going. Vijayakrishnan Sourcing -SNS fashion India.