Costing is given primary importance when sourcing a product. When we delve into the world of knitwear, we realize that fabric cost plays a very important role. It constitutes around 45 – 60% of the total product cost. Hence, making (or) purchasing of fabric at the right price will have a large impact on the final garment cost.

To understand the breakup of fabric cost, we need to dwell deep into the process of knitting fabric.

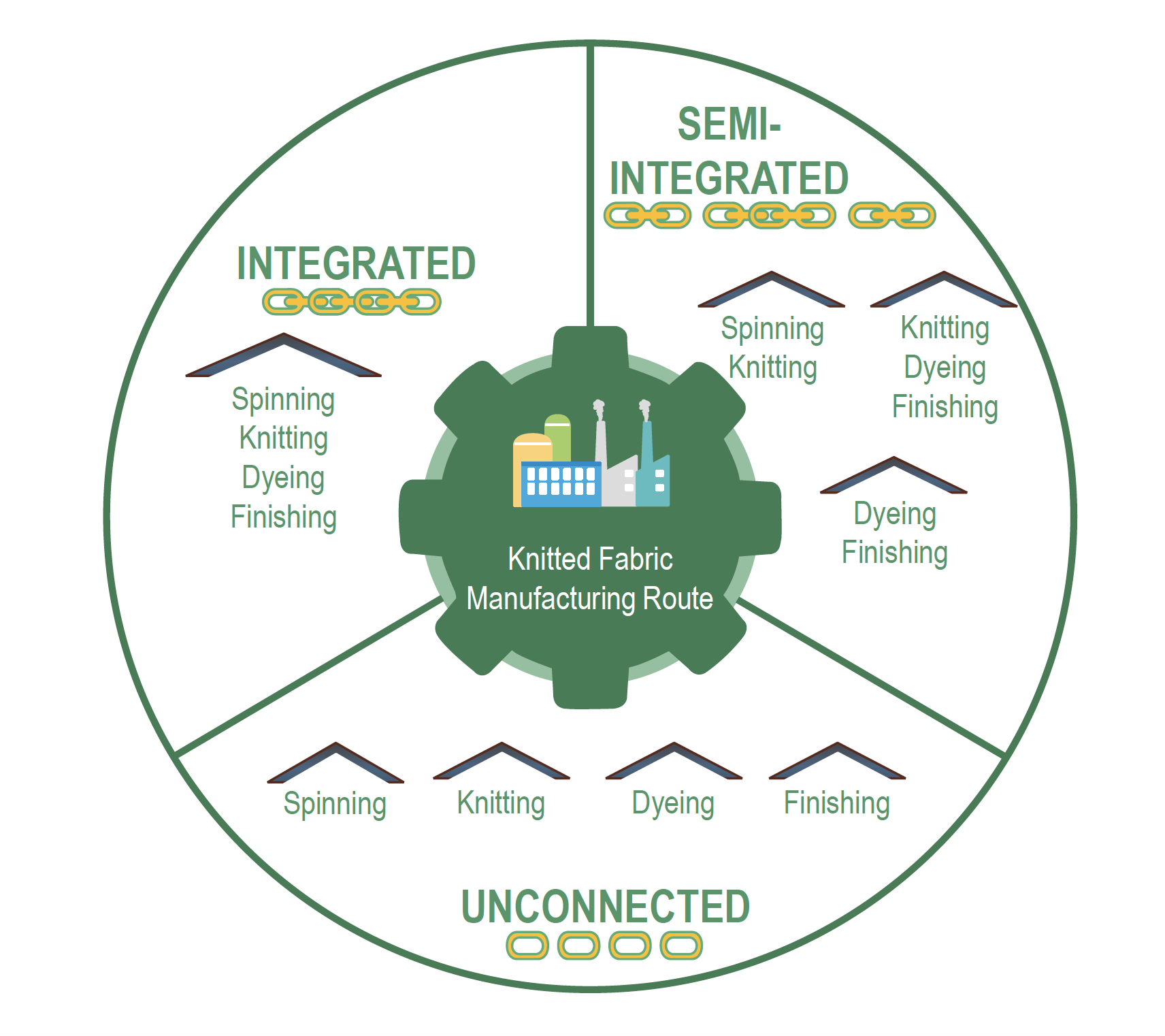

First & foremost, let’s understand the different process routes of knitting fabrics.

As the word explains it, in the integrated route all manufacturing processes take place under one roof. Right from Spinning of yarn, Knitting, Dyeing to Finishing!

A fabric manager should know both the technicalities (i.e., additional processes) involved in fabric as well as required fabric quantity to decide the process route. For example, fabrics like AOP needs additional compacting and rotary printing, stretch/poly fabrics need heat setting / stentering and fleece fabric needs brushing.

Each process route has its costing implications and quality results. The process route should be decided based on the end requirement.

In my view, the integrated route is the best-suited one for bulk quantities. Here, specifying the fabric requirements, quantity requirements, and closing the commercials are enough to start fabric making. Complete risk is borne by the fabric mill; right from procuring the yarn to the supply of finished goods. Fabric procurer’s work will be to give approvals and monitor T&A. If fabric is rejected at any stage, the mill has to bear the responsibility to remake the fabric within given timelines at no extra cost. Because of the risk involved, large investment, running cost etc., fabric cost will be at least 5% higher than other process routes. The advantages of this route are that the garment manufacturer gets final fabric for this price along with test results. Better negotiation will further reduce the costs. The fabric mills procure all their raw materials in bulk at lower costs compared to others. Their machineries will also have better utilization and output. The disadvantage is that the lead-time will be higher as the mills have scheduled runs.

Let's look at the Semi-Integrated process route & its implications. In a scenario where spinning and knitting are combined under one roof, greige fabrics can be procured at the price of buying yarn. The current tax policy renders an advantage to this route. Most of these mills have greige stock, which saves a lot of time. The primary disadvantage here is the availability of limited machine diameters which impacts the per garment consumption. To finish the balance processes, a garment factory will need a competitive fabric team to ensure quality is maintained. This route has an average risk & the fabric cost will be lesser than the Integrated route.

The unconnected process route is usually followed by small garment factories (or) for small garment orders. The process from yarn purchase to fabric finishing is done in small job work units. Here a very strong fabric team is required for consistent follow-ups. The risk is higher as the fabric team has to bear the responsibility of fabric quality. This route is cheaper than the other two process routes. The cost of each process is based on the commercials like immediate payments, which works out cheaper.

Whenever a garment order is confirmed, deciding the fabric process route by the fabric team is very important to get the right cost of the fabric.

Nowadays we see that brands are reducing the order quantities considerably. In such a scenario, the Semi-Integrated process route gives the cost-benefit at average quality risk. In case of higher-order volumes its always recommended to go for an Integrated route.

RELATED TOPICS:#Knit Fabric,Costing,Sourcing,Textiles,Apparel,Fashion,Integrated Mills,Cost,Satheesh Kumar

Leave a comment

Our email address will not be published. Required fields are marked *

51 Comments

RAMESH BABU L RJun 14, 2020 at 12:47 pm

Nice article Sir! Presentation is good! Expecting more in future!

KarthikJun 12, 2020 at 15:16 pm

Hi sir useful informations

TamilJun 12, 2020 at 09:58 am

This was informative , and gives us an idea and initiative to purchase greige fabric - semi integrated form, from the mills , this could really save time and also we can get complete greige qty as per po , without any knitting loss , yarn loss and also the mills informed they will give grey inspection reports as well , thanks for the information sir , expecting more blogs from your end

Loganathan DyStarJun 10, 2020 at 11:53 am

Keep Rocking dear Satish !! Really it's a eye opening for those who wanna start up a business as well as from the B&R prospects. Don't give a break ,just continue !!!

Jayakumar SrinivasanJun 10, 2020 at 11:36 am

Very nice article @Satheesh, Impressive content.

GopalakrishnanJun 09, 2020 at 11:05 am

Hi satheesh, the content is very much useful. keep it up.

Dr.G.K.BalamuruganJun 09, 2020 at 09:19 am

Very informative and useful.

PrasadMay 29, 2020 at 19:40 pm

A complex system described clearly in simple words. Loved your way of explaining it. Keep going Satheesh !

Satheeshkumar DharmalingamJun 05, 2020 at 07:10 am

Dear Prasad, Thank you for your valuable comments. As you said knitted fabric manufacturing and its costing is a complex system, understanding it in a better way will surely save some cost. Keep reading my blog, lot more to come.

JayakumarMay 28, 2020 at 10:39 am

Hello sir, its good to see you in the blog writing.. I keep learning from your experience and i am eagerly waiting for more updates.. Good Luck..

Satheeshkumar DharmalingamMay 29, 2020 at 10:39 am

Hi Jayakumar, thank you for your comments, keep seeing Inside Apparel, lot of interesting and useful blogs are about to come.

Ravindra ChawlaMay 24, 2020 at 07:36 am

Hi Satheesh...Thanks for sharing your knowledge and experience on various fabric process and the way they they become the key factors effecting the fabric cost. Really appreciate on your explanation part, used simple words, which goes easily in mind. Will be awaiting to learn many things from your vast experience in upcoming blogs. Great going.

Satheeshkumar DharmalingamMay 24, 2020 at 13:44 pm

Hi Ravi, Really you have understood right, there are lot of new articles coming in, keep reading Inside Apparel and give your valuable comments.

Kalaiamuthan pMay 22, 2020 at 20:04 pm

All the best satish.

Satheeshkumar DharmalingamMay 24, 2020 at 13:42 pm

Dear Kalai, Thank you, pls support by regularly reading my blogs and post your comments.

Vallari gadreMay 22, 2020 at 15:14 pm

Hi Satheesh sir, very useful article. Great information.

Satheeshkumar DharmalingamMay 24, 2020 at 13:41 pm

Hi Vallari, Good to hear from you, its long time. Keep reading and give your valuable comments.

SrinivasuluMay 18, 2020 at 17:34 pm

Hello Satheesh, Congratulations on your knits article blog published.. it's very informative and useful.. Keep sharing like this..all the best ??

Satheeshkumar DharmalingamMay 24, 2020 at 13:38 pm

Hi Srinivasalu, Thank you for your support, pls read my blogs continuously and give your valuable comments.

Maneesh sainiMay 18, 2020 at 17:13 pm

Hi sateesh great hearing from you truly helpful hatsoff for.such a great initiative

Satheeshkumar DharmalingamMay 24, 2020 at 13:40 pm

Hi Maneesh, Thank you for reading, pls go thru Inside Apparel regularly, you can see lot of good articles coming...

S.veerichettyMay 18, 2020 at 15:25 pm

Hai ,..very good learning , thanks for sharing your experience ..

Satheeshkumar DharmalingamMay 24, 2020 at 13:37 pm

Hi Veeri, Keep reading and learning, pls support with your comments.

SenthilkumarMay 18, 2020 at 15:18 pm

Hi Satish It was nice article and useful information to all. Keep sharing like this and all the best.

Satheeshkumar DharmalingamMay 24, 2020 at 13:34 pm

Hi Senthilkumar, Sure will keep writing articles, as said by you it will be very useful for our apparel people, pls continue your support.

Chetan PawadiMay 18, 2020 at 15:07 pm

Sir the information given very useful & practical.

Satheeshkumar DharmalingamMay 24, 2020 at 13:32 pm

Hi Chetan, Pls keep reading Inside Apparel, you can see lot of useful articles by experts.

Chaitra RamamurthyMay 18, 2020 at 14:30 pm

This is great! Will help everyone from the industry!

Satheeshkumar DharmalingamMay 24, 2020 at 13:31 pm

Hi Chaitra, Well said, pls continue your support.

Mahantesh NaikMay 18, 2020 at 14:03 pm

Hi Satheesh sir, You are the master of knits wear product and sharing your knowledge will inspire us in digging more into the flexible products of inner and outerwear. Thanks

Satheeshkumar DharmalingamMay 24, 2020 at 13:30 pm

Hi Mahantesh, Thank you for your comments, keep reading, lot more articles to come.

Suresh Kumar GMay 18, 2020 at 10:53 am

Hi Satheesh, When I thought if reading a blog had a mind block that these would usually be in jumbling of words to give a professional outlook but to the contrary the details are given in simple and easy way of understanding so that it can reach every needy Continue doing it....

Satheeshkumar DharmalingamMay 19, 2020 at 12:44 pm

Dear Suresh, you are correct, always simple writing will reach easy and understood right. Thank you for your valuable comments, pls continue your support.

SivagurunathanMay 18, 2020 at 07:55 am

Sathish it is great beginning to service it back to industry and wish u all the best

Satheeshkumar DharmalingamMay 19, 2020 at 12:41 pm

Hi Sivaguru, Well said, will do the best to our industry, pls read my blogs continuously and give your valuable comments.

SHAKTHI YARNSMay 17, 2020 at 12:40 pm

Hi bava Great work. your initiation of this work (blog) will help the people who wish to learn about Apparel industry. warm welcome.

Satheeshkumar DharmalingamMay 19, 2020 at 12:39 pm

Hi Bava, Thank you for your comments. Sure, will give more articles useful to the apparel industry.

ParameshkumarMay 17, 2020 at 10:02 am

Hi Satheesh sir, very much informative with available options around us to choose the fabric-route based on need. Thanks for your inputs & much beneficial to everyone. Keep sharing like this ?!!

Satheeshkumar DharmalingamMay 19, 2020 at 12:37 pm

Dear Paramesh sir, Thank you for your comments, as said these information will be surely helpful. Keep reading and support.

BHASKAR NMay 16, 2020 at 11:08 am

Good initiative. All the best Satheesh.

Satheeshkumar DharmalingamMay 19, 2020 at 12:34 pm

Hi Bhaskar, Thank you. Keep reading the articles in this blog and give your valuable comments regularly.

KarthikMay 16, 2020 at 23:07 pm

Very nice and useful information sir.

Satheeshkumar DharmalingamMay 19, 2020 at 12:35 pm

Hi Karthik, Good to see you reading my blog. Keep reading and give your valuable comments.

Dr. K SaravananMay 16, 2020 at 10:52 am

Excellent. This kind of information will help the freshers or budding technocrats.Proceed this initiative.

Satheeshkumar DharmalingamMay 19, 2020 at 12:32 pm

Dear Dr KS, Thank you for your comments. Even am sure that it will be more informative to the young textile and fashion technocrats. Pls support me with continuous reading of my artciles.

Sourabh KumarMay 16, 2020 at 09:37 am

Very effective and useful detail with explanation sir ??

Satheeshkumar DharmalingamMay 19, 2020 at 12:26 pm

Hi Sourabh, Thank you for your comments, keep reading the articles in this blog, good set of new articles are about to come.

SehgalkamalMay 16, 2020 at 06:31 am

Hello Satheesh. Good to see you on this side as well. This indeed a very informative and educative post. Keep sharing... All the best. Warm regards

Satheeshkumar DharmalingamMay 19, 2020 at 12:23 pm

Hi Kamal, Thank you for your comments, will do continuous informative posts, keep reading.

Kamal sehgalMay 16, 2020 at 06:30 am

Hello Satheesh. Good to see you on this side as well. This indeed a very informative and educative post. Keep sharing... All the best. Warm regards

KamalsehgalMay 15, 2020 at 05:59 am

Very effective and very true. thanks for sharing such wonderful post..super post bro. Kamal