In the last article we understood that the objective of finishing is to improve the look and/or serviceability of a fabric. Textile fabrics are finished either physically/mechanically or by using chemicals. Thermal finish is also popular on thermoplastic materials to produce a desired effect like permanent pleats on polyester fabrics.

It is difficult to classify the finishing processes as they are varied. For example, if we consider cotton, several finishing processes are used widely, but they are so varied in techniques that it is difficult to group them together.

We know only about the finishes given on our regular daily use fabrics, but finishes applied on textile materials used in various industries are very wide and specific. Common example is waterproofing finish applied on umbrella and raincoat fabrics.

Many finishing techniques/chemicals are not published, as they are maintained as trade secrets. We can only understand the overall results of those performance or functional finishes. Technicalities of some specific chemicals which serve specific functions are not declared to market.

Mainly the variations of finishing depends on the factors like;

- the type of fibre and its arrangement in yarn & fabric,

- the physical properties of fibres such as swelling capacity and the behaviour when pressure or friction is applied,

- chemicals absorbing capacity of fibres,

- susceptibility of the materials to chemical modification and

- the desirable properties of the material during its use.

If the property of a material is already good, then finish on it can be minimal. For example, lustre of silk is good, so little finishing is necessary. Minimal finishing on worsted wool is enough as the raw wool is treated at the fibre stage. Cotton is given with variety of finishes as it has diversified uses.

In brief, some of the temporary finishes are

- calendaring, embossing, glazing, breaking, stretching applied mechanically,

- starch, china clay and other mineral fillers applied using filling method and applying oil, different softeners on surface.

Few durable finishes like compressive shrinkage, milling of wool, raising & cutting processes, permanent setting are given by mechanical methods, lamination using synthetic resins by deposition methods and chemical finishes like mercerisation, parchmentising, water repellent finish, fire-resistant, fire-proofing finishes, shrink-proofing of wool, etc.

By using suitable chemical and/or physiochemical techniques various functional properties can be improved in fabrics. Simultaneously, the use of polymers instead of chemicals is increasing in order to improve multiple functional properties. To improve the performance of the properties of fabrics and fibrous materials, some modifications in the properties should be made, which are resistance to wrinkling, fire, soils and stains, water, micro-organisms and insects, light, heat and cold, shrinkage, air pollutants and chemical agents, mechanical changes caused by abrasion, pilling and various types of deformation and build-up of static charge.

Some functional finishes to understand are given below :

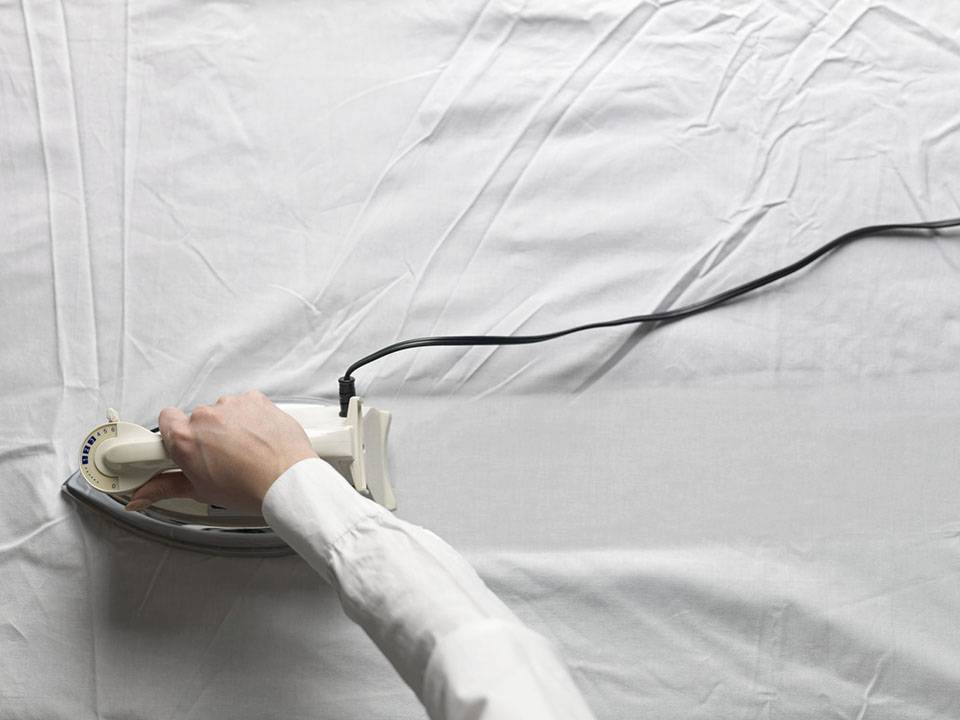

- Wrinkle resistance or resiliency, applied for cellulosic fibres and their blends with synthetics. This fabric does not wrinkle easily which means it has the ability to resist the formation of creases or wrinkles when slightly squeezed. It is also called as easy care, minimum care, easy to iron, no iron, crease-proof, create-resistant, wrinkle-proof, durable press, permanent press etc. in the market. Here, resins of plant or synthetic bases are used to finish the fabrics.

- Flame retardancy, applied to most natural and synthetic fibres. Fabrics described as flame retardant are ones which do not support combustion and are self-extinguishing. In case of accidental fire, this type of fabrics will not contribute to the spread of flame. This finish is done to protect the consumers from unsafe apparels. Firefighters and emergency personnel require protection from flames, as do floor coverings, upholstery and drapery. The military and airline industries also have multiple needs with regards to fire retardancy. The flame-retardant chemicals and formulations are also numerous and include halogen, phosphorous, nitrogen, antimony, sulphur, boron and other elements in many forms and combinations. Terms like flame-resistant, flame-proof and fire-proof are often meaningless or misleading because nearly all fabrics are combustible to some degree.

- Absorbency, done usually to impart hydrophilicity to synthetic fibres as natural fibres have certain level of moisture/water absorbency properties in-built to it. Wetting, Wicking, Moisture vapour transmission are terms used here. When humans sweat during different activities, the fabric needs to transport the water from body surface to the atmosphere and make the wearer feel comfortable. It is an important factor in optimising comfort and maximising performance of a fabric. These finishes are usually applied to towels, inner wear, active wear and other products where moisture absorption is important. The manufacturers of sportswear continuously strive to improve the moisture management properties of the garments, and so there is a great potential for growth in this field. Acid and alkali treatments, enzyme usage are common practice, plasma treatments are also carried out to increase the absorbency of materials.

- Soil release, primarily done for synthetic fibres and their blends. The need for soil-release chemicals was realised after the introduction of polyester/cotton blends in the early 1960s. A soil-release property is the clean-ability of fabrics by the laundering process. The release finish allows stains to be removed more easily during laundering compared to most common untreated fabrics. Finishing chemicals with fluro carbons, carboxy based, hydroxy based, ethoxy based etc. are used to give this soil release treatment to the fabric.

Let us see few more functional finishes in my next article …. Part 3….

RELATED TOPICS:#Apparel,Fashion,Innovation,Product Development,knit,Fashion Design,fashion industry,textile industry,apparel industry,creation,innovation strategy,Satheesh Kumar

Leave a comment

Our email address will not be published. Required fields are marked *

9 Comments

Anita Jemima XavierSep 05, 2020 at 16:32 pm

Very Informative Sir, You don’t stop to inspire me in everything you do. Iam glad I get to learn from your blog now.

Sanjay lalSep 04, 2020 at 21:33 pm

Dear Satheesh, Read you article. Very informative. I always learn something of value through your articles. Thank you.

Ramesh.gSep 04, 2020 at 14:54 pm

good one satheesh, very crisp & informative to the point. useful for many of us...

Steephen AnthonySep 04, 2020 at 13:07 pm

Hi Satheesh Very informative article. Very good

GopalakrishnanSep 04, 2020 at 10:23 am

Nice article to read

ArunaSep 04, 2020 at 10:03 am

Very precise.. Feels like brushing up the technical points..

Raghav RaoSep 04, 2020 at 09:59 am

Understanding of the key elements of the subject matter expertise is so clearly written. Thanks to our Sateesh Sir, for doing this noble work.

S.VeerichettySep 04, 2020 at 09:58 am

Nice initial brief on performance finish.. awaiting to see the next article on this...

Sukumar KAug 23, 2020 at 10:05 am

Various finishing needs and types are explained in brief especially short and sweet.