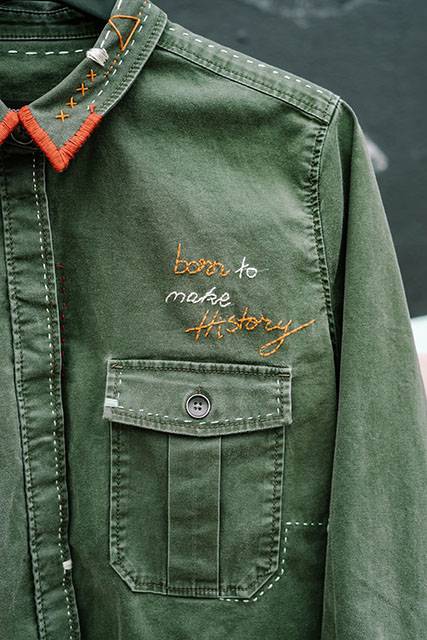

Color approvals & print approvals were the topics of discussion in my previous blogs. In continuation, this blog covers the various aspects of embroidery approvals.

Embroideries are usually associated with the Indian Ethnic wear market, but it is surprising to see the space it occupies in men's, women's, and kid's western wear range too. Embroidery designers play a very important role in the making of amazing embroidery patterns. They keep developing new embroidery designs based on the season, region, culture, products, and also based as per buyer’s requirements. Traditionally in many homes of India, hand embroidery is taught to girls to decorate their sarees, blouses, handkerchiefs, pillow covers, sweaters, etc.

We all know that embroidery is a hand done craft of decorating fabrics using threads. Apart from many varieties of threads even pearls, beads, other shaped fabrics as appliques, glass pieces, quills, sequins, etc are used in embroidery. Different sizes and types of needles are used to bring out creativity.

Embroidery is classified into two :

- one is based on the base material used and the relationship of stitch placement to the fabric (eg: free or surface embroidery, counted embroidery, and needlepoint or canvas work)

- other is based on the similarity of appearance (eg: drawn thread work, cutwork)

Chain stitch, buttonhole or blanket stitch, running stitch, satin stitch, cross stitch are some of the basic stitch techniques used. Even today these stitches remain the fundamental techniques in hand embroidery.

Whether it is a hand or machine embroidery, understanding the base fabric, design intricacy, design size, needle size, thread count & ply, thread quality, thread variety, accessories, embroidery backing, etc. is very important to all the people involved in making embroideries. For e.g garment designers, merchants, embroidery designers, and embroidery workers.

Designer’s Point of view & comments :

- Expects the embroidery to come correct as per their expectations

- Try to provide clear artwork files but still, the embroidery designer says the artwork given is unclear

- Had given two files separately for print and embroidery but expect to see both combined in all actuals. The factory is submitting separately on different days, how can I approve it?

- I have asked for a satin stitch in the center but the strike-off received is in fill stitch.

- I want to see the strike off in Pique fabric, but it's been submitted on jersey fabric.

- Logo required in 2.5 cms width, but it is 2.7 cms, re-submit

- Embroidery received is so stiff, need it soft and flexible

- I want the edges of embroidery to be clear but it is always serrated

- The base fabric is visible, increase the number of stitches (but the embroidery should not become stiff)

- I need 3D effect in this embroidery, received strike-off is flat

- Use only 3 layers of backing foam, why you have 4 layers? because of this embroidery has become stiff

- Embroidery should not get tinted in garment dyeing program

- Am giving all my embroidery developments during the sampling stage itself, but still, the factory cannot get it closed till production, am forced to approve the closest in order to avoid production delay

Factory Merchant’s Point of view & comments :

- The designer doesn’t give artwork hardcopy, it is given only in soft copy

- Designers think print and embroidery are the same, they want print like clarity in embroidery

- Letters are very small, how we will get clarity?

- Placement may not be perfect, when framing is done it may move a little but my PP sample got rejected because of this little displacement.

- Embroidery is not possible above the HD print, but this designer doesn’t accept it.

- Needle holes will be visible on Non-PVC or Gel prints, how to avoid?

- Cannot make such heavy embroidery on this low GSM fabric, will get holes on the fabric, but the buyer is not accepting, they need it somehow.

- If the number of stitches is increased to get more clarity and cover the base, then embroidery becomes stiff, also the cost will go high.

- Maximum satin stitch width is 1.2 cm but the designer needs the center portion of the design which has a 2 cm width to fill with satin stitch instead of fill stitch, why this designer doesn’t accept it if we say practically it is not possible or it's not production feasible?

- The designer is rejecting/changing the all-over embroidery design, this embroidery machine unit is taking more than 10 days for the next strike off as they need to change the settings of the total machine from placement frames to all over frame even to make a strike-off, but this buying merchant keep pressurizing me for re-submit

- The buyer is asking me to make embroidery in Barudan machine only, but our in-house embroidery machine is Tajima, owner is not accepting to do outside job work and he is asking me to convince the buyer to do in Tajima.

- The buyer’s requirement is to use Freudenberg 4 way tearable foam but the cost given for embroidery is nowhere close to using this foam quality

- Why can’t designers choose thread shades from Coats embroidery thread shade book which has hundreds of shade in it and they can mention it directly in the tech pack? Every time they give some Pantone number and we keep submitting options for approval.

- The designer wants embroidery thread to match the fabric base color, I have submitted more than 5 options and now it has to be dyed to match. Thread supply lead time for both sampling and bulk, MOQ will not match, we will order extra cones to meet the MOQ and it will be lying idle in trims stores.

- Connecting threads are to be cut between texts even in a small embroidery, this reduces productivity as the machine should stop and start every time. Machine trimming takes more time and manual trimming many times damages the base garment which takes to garment rejection.

- For 300 pieces order, how can we do new Schiffli embroidery, cost will be very high for both development and bulk, why can’t the buyer go with stock fabric?

Above are very few comments and views from designers and factory merchants. Other persons in this chain are the embroidery designer and embroidery worker (machine operator). Making them understand as per the designer’s requirement and their comments given is a big task for the factory merchant. A typical example of asking to submit thread options in embroidery strike-offs form is also witnessed. We often see even after the bulk fabric is inhouse, artworks are not approved.

Nowadays, embroideries are also done in caps, coats, blankets, shoes, denim, stockings, masks, etc. Here a basic understanding and cooperation are very much needed from both buyer and factory side to run the production smoothly.

See you in my next article, follow me…

RELATED TOPICS:#Apparel,Satheesh Kumar

Leave a comment

Our email address will not be published. Required fields are marked *

5 Comments

VgkOct 04, 2022 at 04:01 am

sniemy ejrtkb adqzkjg cfoxnj tfuefj cseyrz

KumarDec 21, 2020 at 11:13 am

Hi sir, Good morning! Today I was read Super and interested subject and thanks to you for the same.. I don't see it's kinf of article, actually it's same like what I heard from factory and designer..

KumarDec 21, 2020 at 11:13 am

Hi sir, Good morning! Today I was read Super and interested subject and thanks to you for the same.. I don't see it's kinf of article, actually it's same like what I heard from factory and designer..

Akhil KhannaDec 20, 2020 at 21:22 pm

Good article. India we are still not utilising the potential of Embroidery software’s fully

S.VeerichettyDec 20, 2020 at 09:16 am

Nice practical points written...