THE SUSTAINABILITY SERIES

Article 4 of 5

In the last article I discussed the importance of a Sustainable Development Strategy and the critical elements that the strategy should encompass. Taking the discussion forward, on what brands should do to ensure their part in the Sustainable Development, I shall be discussing in this article some of the easiest changes that can be done to kick start the journey of Sustainable Development.

Let’s first understand the process to identify…

Sustainable development is a long and continuous journey that has the potential of infinite opportunities for organizations. However, there are some low hanging fruits that an organization can pluck almost immediately. The relevance of these however, depends on what is the material issue for the organization, identified in consultation with relevant stakeholders.

Simultaneously, a life cycle assessment can guide organizations in identifying the areas with maximum potential of reducing their ecological footprint.

Life cycle assessment (LCA) is a cradle-to-grave or cradle-to-cradle analysis technique to assess environmental impacts associated with all the stages of a product's life, which is from raw material extraction through materials processing, manufacture, distribution, and use. An LCA study involves a thorough inventory of the energy and materials that are required across the value chain of the product, process or service, and calculates the cumulative potential environmental impacts.

An apparel organization that has just started or is looking to start its Sustainable Development journey can adopt some of the following to kick start their journey:

1.Clean energy

Despite several policy paralysis for adoption of clean energy in India, this is still one of the easiest shifts. This not only helps organizations mitigate the carbon dioxide emissions from their operations but also generates economic value for an organization. This is why it is almost always an easy discussion with the business teams. The ROI and Payback period is becoming more and more lucrative with strides in innovation and the decreasing CAPEX requirements for renewable energy adoption. However, the ongoing trade war and the impact of COVID-19 may make the adoption challenging.

a. Solar Power

There are several models that an organization can choose to adopt solar power, including the rooftop solar panel (Both CAPEX and OPEX models), open access wheeling model or the group captive consumption model. However, the market barriers created by the state discoms and the policy paralysis at the central level makes it difficult to shift to solar energy at a large scale until you have large space and/or the required free cash flow.

b. Wind and Hydro Power

Organizations may also adopt Wind energy or the Hydropower but these, due to limitations on inter-state electricity distribution, are geographically limited. Organizations can enter into direct contracts with hydropower and wind power producers or have their own captive wind power farms.

c. Biomass based power

Another option with a high potential but low adoption rate is the biomass based energy that can be generated from crop waste (both 1st and 2nd generation) including but not limited to rice husk, coconut shell, waste from wood chip industry, and the renewable plantation like Juliflora plantation. However, one has to be careful to ensure that the biomass feed is not coming from forest or the farmlands diverted for fuel crops.

2. Energy efficiency

At present, India is still a net energy deficit country, some states witness a gap between the supply and demand of energy while very few are surplus. As a result efficient supply and demand management both play an important role to ensure efficient energy utilization.

There are a number of interventions that an organization can plan to reduce the demand and hence achieve energy efficiency within the operations. Some of the easiest ones to adopt include:

- Shifting the electrical installations to LEDs to reduce the overall demand

- Undertake periodic electrical and energy audits to check health of infrastructure and identify improvement opportunities

- Undertake periodic maintenance of the equipment

- Implement AI based energy management within the operations. This has potential to reduce behavioral based wastage

3. Sustainable fabric

This is a tricky area with so many different claims around different products and hence one has to be careful while selecting a sustainable fabric. To start with, the easiest option is to replace a certain percentage of conventional cotton with Better Cotton Initiative (BCI) cotton or organic cotton. There is definitely a cost implication with the adoption but with time this can be reduced. (Note: It is important to ensure that transparent 3rd party certification is available for the claims)

Lyocell fabrics manufactured using sustainable wood and a closed loop system that uses non-hazardous chemicals is another option that can be adopted to increase the mix of sustainable fabric in the product range.

Further, recycled fabric of good quality, produced using the pre-consumer waste is now easily available. Though, due to more prevalent technology of mechanical cycling the fabric may be utilizable for a certain category of products. It is important to ensure that the recycled fabric and the entire value chain is GRC (Global Recycled Standard) certified. I have recently come across a non-mechanical patented process for recycling the waste and am eager to understand the potential but for obvious reasons can discuss in detail about the same.

4.Sustainable Packaging

Before we start exploring the options to convert packaging to a sustainable one we need to understand that reducing the need of packaging material without compromising the quality of the product should be the prime focus. This is easily achievable in the apparel sector but requires other functions to align with the objective, including the creation of a dust free warehouse, enclosed logistics to minimize exposure during transit amongst other requirements.

In operations where packaging is unavoidable, the focus should be to design packaging that is reusable to certain extent and then recyclable. Also, potential of increasing the mix of recycled materials in the packaging should be explored. Reverse logistics is the biggest challenge for reuse of the material but I strongly believe that industry collaboration can render it economically feasible.

Furthermore, it is important that an ecosystem is established to ensure that packaging is being actually reused or recycled otherwise despite being reusable and/or recyclable the packaging may still end up in landfill or the oceans. This is one of the most critical aspects of sustainable packaging especially with the challenges posed by packaging waste once it enters landfill or the oceans. Here collaboration across a transparent value chain is essential. Organizations like ‘Plastics For Change’ are doing really good work in this space.

5. Responsible Supply Chain

An organization should first focus on having a Code of Conduct for it’s vendor partners, in line with the local legislation and the Sustainable development vision of the organization. Thereafter, appropriate capacity building of the vendor partners should be carried out on the Code of Conduct and provision should be made for periodic monitoring of its implementation within supply chain operations.

Once the vendor partners mature and align with the organization's sustainable development agenda, appropriate projects should be identified and implemented in collaboration with the vendor partners to improve their environmental and social footprint.

The above are some of the opportunities that can be achieved quickly as policies, in most cases, are conducive for their adoption and a number of alternatives are available for the required shift. However, one should also explore the opportunities that require commitment, innovation and most importantly collaboration amongst industry peers to be successful in the textile and apparel sector.

I will now briefly discuss the challenges that require a well-knit infrastructure of different stakeholders working together to achieve the common goal of sustainable development:

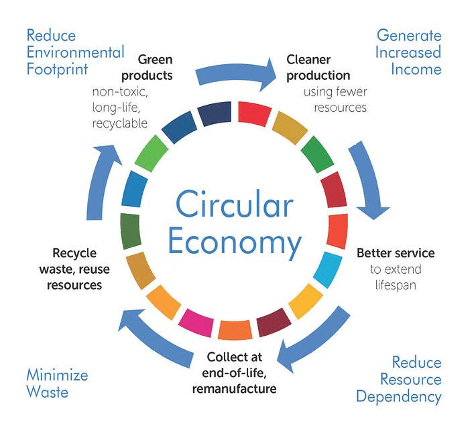

1. Circular economy

Textile and apparel industry generates millions of tons of textile waste each year. Most of this waste ends up in the landfill despite established potential of recycling a larger percentage. Fast fashion is not only pushing the amount of textile waste towards a higher trajectory but is also creating a gap between the demand and supply of the conventional textile materials including cotton.

It is becoming clearer that the linear approach of "make, take, dispose" is not sustainable and organizations have to come together to first reduce the pre-consumer waste and then find options to recycle both pre-consumer as well as the post-consumer textile waste.

Organizations should collaborate to set up the required infrastructure involving innovators, collectors, sorters, recyclers, up cyclers and down cyclers with a clear flow of waste stream to enable the reuse and recycle eco-system.

2. Water neutrality

Freshwater is a scarce resource as only 3% of the total water on earth is considered as freshwater. Out of this, ~2.5% (>80% of the freshwater) is locked in the glaciers, polar ice caps, atmosphere and soil, leaving a fraction of water to meet day to day requirements of biodiversity on earth including agriculture, drinking and industrial use.

Therefore, it is important that water intensive industries like textile and apparel should continuously innovate solutions to reduce dependence on freshwater and create closed loop processes that ensure minimal water wastage. Some of the established solutions that can be adopted by the textile and apparel sector include zero liquid discharge wastewater treatment in manufacturing, utilization of wastewater for production processes (Implemented by Arvind Group where they take waste from local municipality, recycle it and then utilize it for processing) or the utilization of waterless processes for finishing of the garments like the one provided by Jeanologia.

Furthermore, the maximum utilization of water for an apparel product happens in its use phase. To achieve absolute reduction apparel organizations should collaborate with innovators to identify enzymatic and/or chemical (non-hazardous) washes that inhibit the bacterial growth that in turn lead to odour, the main reason for frequent washes. Lastly, decreasing the wash cycle requires cultural and habitual shifts for which it is equally important to educate and transparently communicate with the customers.

3. Sustainable chemicals

Textile and Apparel industry utilizes a large number of chemicals across the entire value chain right from the crop production to processing the yarn and finishing the final garment. Most of these chemicals are toxic or their exact interaction with ecology is unknown. A recipe perfect for disaster with potential to impact many generations.

The textile and apparel organizations should start focusing on this serious risk and shift to non-hazardous chemicals for operations wherever the alternatives are available. The ZDHC (Zero Discharge of Hazardous Chemicals) Foundation is doing a fantabulous job in this space and has launched the Roadmap to Zero Programme.

ZDHC, a non-for-profit organization, provides a repository of alternate non-hazardous chemicals and is helping the fashion industry to gradually move away from hazardous chemicals.

I hope with this and the previous article, I am able to highlight that if an organization is committed and understands that a shift for sustainable development is needed today for a better tomorrow then there are ample opportunities to kick start the journey. Most of the above mentioned interventions are easily adoptable while some require a long term commitment from the industry as a whole.

In my next article I would discuss the importance of ESG compliance within the Supply chain and focus on the debate of whether it is a cost or an investment.

Sustainable development is a continuous commitment for doing the business in the right spirit and is definitely a long term strategy.

RELATED TOPICS:#Apparel,sustainable development,Eco Friendly,Tushar Jindal

Leave a comment

Our email address will not be published. Required fields are marked *

6 Comments

2432Feb 06, 2023 at 01:55 am

2432

646Jan 23, 2023 at 06:09 am

646

Abir basuSep 22, 2020 at 09:08 am

Great article ..the sustainable way for textile is the way forward..the immense value and benefits to environment should be highlighted to consumers to get moving on this way..

TUSHARSep 22, 2020 at 22:44 pm

Thanks Abir. Yes, consumers play a very important role in this journey.

Manoj Kumar M RSep 21, 2020 at 08:03 am

Good article Tushar ???

TUSHARSep 22, 2020 at 22:45 pm

Thanks Manoj.