Anindya's Anecdotes #4

Isn’t it surprising how we all tend to see every situation with the same glasses on? We apply the same standards, measure everything against the same yardstick, have a “one size fits all” policy…

But why?

In the quest to find an answer to that question, I started thinking about an incident that occurred while I was still at my first job. It was the late 80’s/early 90’s. The retail industry had started growing at a fast pace and business was booming.

But then came the 1st disruption in the business!

A formal shirt brand called STENCIL. Tapping in the value segment, they launched cotton formal shirts for Rs.199.

Yes, you read that right… Rs199 it was.

It was quite the rage & had taken the market by storm.

So, Mr. Lead M.All, our chairman, had a quick meeting with my boss Ms. Buying Beauty.

Such projects were nothing new for my boss. She was used to these reactionary projects from the Chairman, every time he came across anything new. And many a times he even forgot some of these projects. But every time he came up with these idea’s, they used to create quite the stir in the office.

So, not realising the importance of one more new project, this was passed on to me.

And so began my indoctrination into product development.

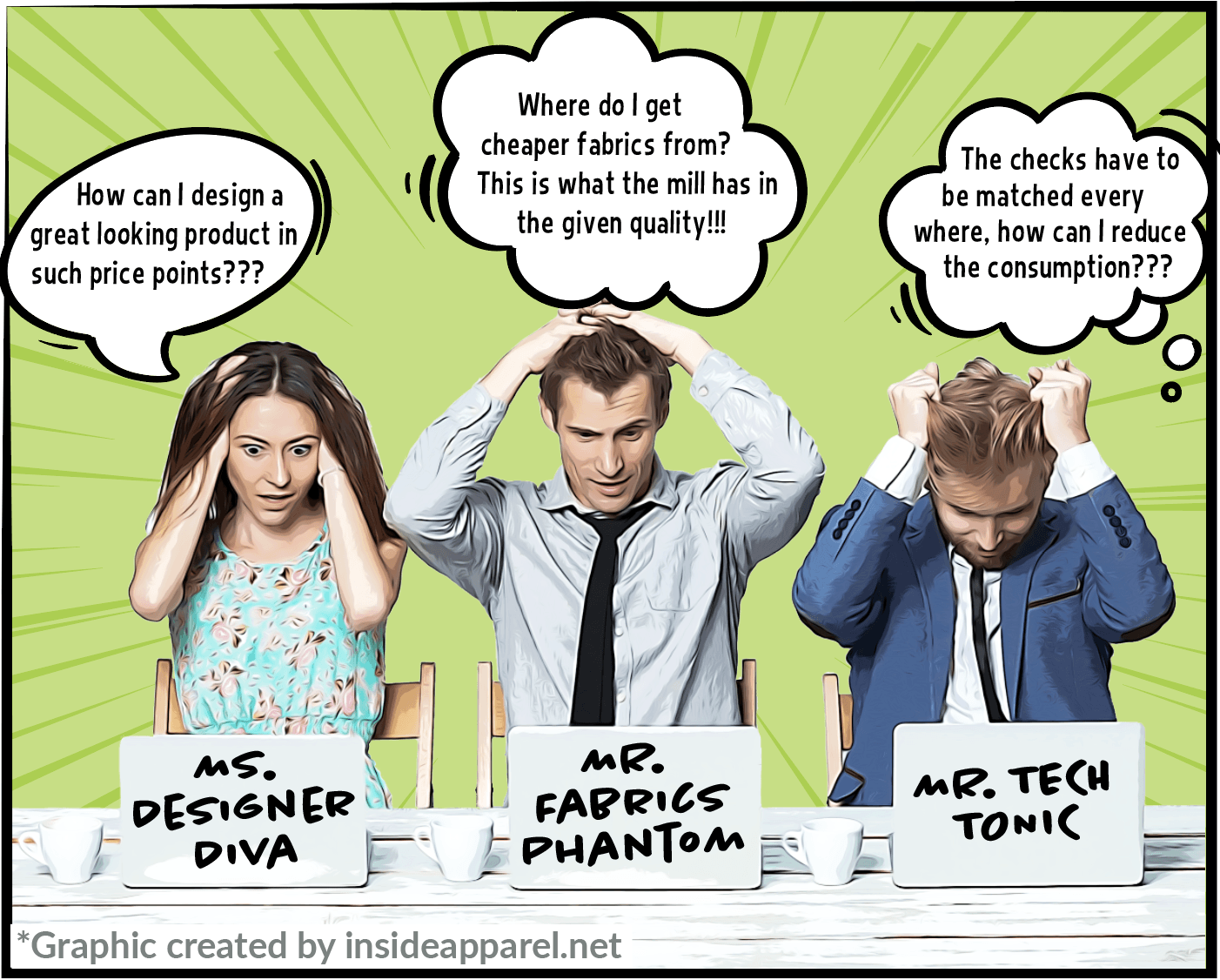

I went from team to team to figure out how to get that product right. Unfortunately success seemed like an elusive dream to me.

From the designer to the fabric team, from the trims to the tech team… Everyone told me the same thing. We are doing the best in the given quality.

A week passed by without any progress.

Then came that day, when the Chairman wanted to know what was taking so much time?

My boss, sitting right beside me was equally baffled by the outcome of this exercise. Cost re-engineering was still not a developed skill set in the company.

And then began a masterclass by the Big Bad Wolf himself. A lesson that has stayed with me ever since.

‘Let’s take away the box pleat at the back. Can we reduce the length by an inch? What about the matching parameters? Do we need shoulder, sleeve, cuff, cuff placket matching? What about the cut and sew placket, do we need it?’ And he then went on to discuss every trim used, thread quality, packing material and lo and behold, in 20 minutes, we had cracked the entry price point shirt.

‘But’, my boss was still not convinced, ‘this is not what our customers expect in terms of quality’. She held her ground.

‘Do you know the difference between the German cars and the others?’ He asked, alluding to his prized Mercedes. In those days it was a rarity in the country. ‘Do you think the quality expectation is the same for these and the others, which are one tenth the cost?’

‘Quality is how you define the specifications, the important thing is, is the consumer accepting it happily?’ He asked us to do a small test market for these in our two flagship stores in Delhi.

The rest as they say is history. Our new price point product did well for sometime; as did that new brand. But as it happens so often, in this graveyard of fashion brands, both have been relegated to the annals of the Indian Fashion Industry history.

Quality is how you define the product specification.

Different customer sets have different expectations of quality at different prices.

And hence, different quality for different folks.

You may think this is simple and everyone understands it. Well, truth be told, most companies struggle with the concept of defining quality differently for different price points and products. They get used to following the same standards for everything in the company and this leads to higher costs and longer lead times, to name a few.

What are your experiences with this? Please do share your point of view for all our readers.

RELATED TOPICS:#Apparel,Anindya Ray

Leave a comment

Our email address will not be published. Required fields are marked *

13 Comments

AmithNov 22, 2020 at 21:49 pm

Test Reply

AmithNov 22, 2020 at 21:59 pm

Test Reply to comment

AmithNov 22, 2020 at 21:46 pm

Test Comment

Steephen AnthonyNov 08, 2020 at 11:30 am

Yes the quality depends on the nature of the customer segment it is being produced for. In every business this kind of high & low quality standard is very obviously present. It's up to the retailer to take a call whom they want to cater for. Yes " different quality for different folks"

RayanindyablogsNov 08, 2020 at 16:29 pm

Absolutely, but it is very difficult to practice this in organisations

NazmulNov 08, 2020 at 10:15 am

A Lot of thing are interrelated behind a decision and its very true that quality matters. Its making sense, well written Sir. One thing is obvious, if the cost cut is to reduce product cost or increase profit margin, product standard be compromised as a result inevitably which is interrelated with brand image and reputation.

RayanindyablogsNov 08, 2020 at 16:28 pm

Thanks Nazmul.

Anindya RayNov 07, 2020 at 10:16 am

Ha ha Sanjay . . well said . . though not this example . .

Anindya RayNov 07, 2020 at 10:14 am

Thanks Gaurav

RayanindyablogsNov 07, 2020 at 10:13 am

Thanks Prashanth. Yes this is an exercise that has been done many times since.

Prashanth HvNov 07, 2020 at 09:41 am

I too have gone through this kind of exercise with you on Newport jeans. It was a great learning and I still remember. This kind of re-engineering is still helping me many times where I have to achieve certain targets without compromising on the overall Outlook of the garment and it works.

Gaurav rahejaNov 07, 2020 at 09:15 am

This article makes complete sense, specially in today’s context. Where consumers have enough and more options to choose from and the on going argument between online/offline channels for sales and profitability. I agree that “quality” can be a critical parameter to differentiate business strategies between these channels.

Sanjay lalNov 07, 2020 at 07:53 am

Shows that the retailers are the root cause of Fast Fashion, the root cause of environmental damage and how the generations will have ro pay the heavy price in years to come. Retailers make a quick buck at the cost of future generations.