In this article I would like to emphasize on key dimensions of Quality standards that we usually miss or tend NOT to define .

My experience states that Fabric, trim and construction techniques must work together to create a professional-looking garment. The fabric should have the correct weight and drape for the design. Finishing details should complement the fabric and the garment. The garment should look attractive, even and appropriate, both on and off the body. The garment fit should be becoming and reflect current fashion trends. Construction techniques should not be obvious nor distract from the total garment.

DID WE DEFINE STANDARDS?

A Quality standard is a documented process intended to control work resulting in a certain level of excellence (quality). The standard’s degree of control is a basis for its selection for achieving that level of quality.

My observation is how do we define standards . Some examples will illustrate this.

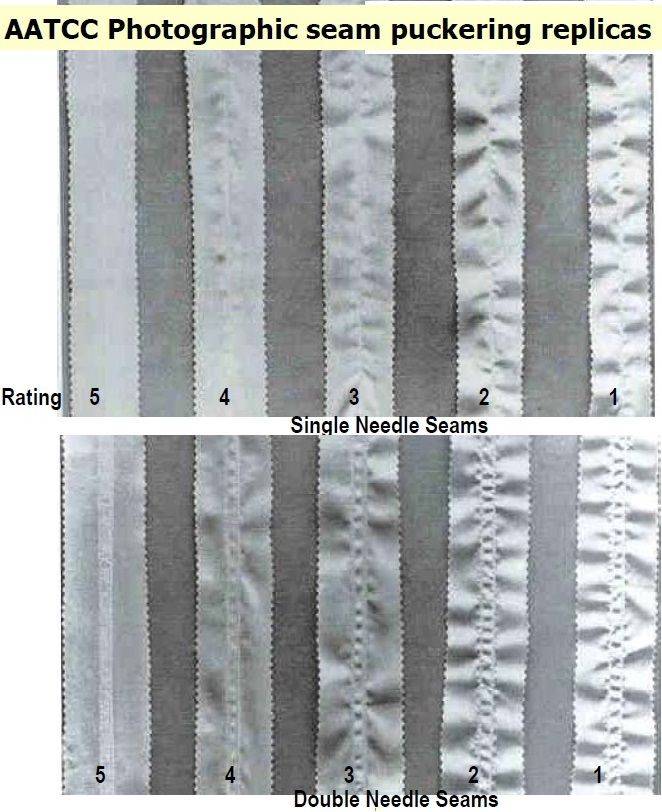

A. Puckering standard: Though there are multiple reasons for Puckering like sewing thread tension,thread shrinkage, stitches per inch, differential feed,fabric shrinkage there must be a rating defined on a scale of 1-5.

B. Shades : There has always been an ambiguity in giving shade approvals. We usually tend to classify shades into A,B or C and Reject . We must mention the grey scale rating which is technically correct.

A grey scale is used for evaluating the color shading between products and client’s approval sample or among pieces in production. Grey scaling has grades 1-5 and increases by half of grade (1, 1 1/2, 2, 2 1/2 and so on..) with 5 being the highest. General speaking, most of overseas clients can accept above grade 4 , while some can accept the grade 3-4.

C. Lab Dip Approval: It is our expectation that lab dips must to be approved by the 1st or 2nd round of submits. The standard criteria must be defined along with Light source.

On Spectrophotometer, the Delta E tolerance and LCH L* = lightness C* = chroma H= Hue values

- i.Knits and Woven s: dE1.0, L0.8, C0.4, and H0.4

- ii.Sweaters: dE1.0, L0.8, C0.5, and H0.5

D. Light Sources: The primary light source is D65. One must match the lab dips to the standard in D65. The secondary light source is CWF (Cool White Fluorescent).The tertiary light source is IncA (Incandescent A).

E. Thread: What that actually binds the parts of that converts into a Product. The most significant parameter do we know that the thread properties are technically associated to Tensile strength, Tenacity, Loop strength, Elongation , Modulus ,Elasticity, Shrinkage Moisture regain and heat resistance. We must define Thread quality against every fabric quality.

F. Stitches Per Inch: Tech Pack detailing must define the Stitches per inch for every seam. Define SPI for Top Stitch, Overlock specifically. This is an important factor again classified from fabric construction and fabric Type.

Specifying tolerances for garment dimensions

There can be a major hue cry on specifying tolerances. It has multiple factors on the behaviour of Raw Material, The garment process , the method of measuring and so on. The key is at what stage should this get highlighted and who is accountable to consider all this factors. On bulk production, can these tolerances can really meet the specifications??

Accessories -Closures , Buttons, Zippers.

Most garments aren’t simply a few pieces of fabric stitched together. Rather, they also include functional accessories like buttons, snaps, zippers, ribbons and elastic bands. Most consumers find poor quality closures to be a nuisance and frustration to repair. A single failure on any functional garment is a dead reject and impact of MRP.

I prefer to suggest some tests to include always

- A.Pull test: Pull at the accessory with a pull gauge for 10 seconds to confirm it stays securely attached to the garment.

- B.Fatigue test: Use the accessory as intended for 50 cycles (e.g. button and unbutton 50 times) in quick succession and confirm it’s still functional and the garment is undamaged after testing.

- C.Stretch test: Stretch elastic bands and straps for proper elasticity and check for any breakage in elastic fibers or stitching.

Conformance to Statutory laws for garment labeling

What I commonly find is the imprint or declaration of product information. This is the right to information for the consumer.

- Fiber content of clothing -Major composition of Body and Lining or Trim must be mentioned and also must comply with the Textile Fiber Products Identification Act

- Country of origin: where the item was manufactured or where the most significant manufacturing process occurred

- Manufacturer identity: either the company name or the Registered Identification Number (RN) of the manufacturer, importer or another firm marketing, distributing or otherwise handling the product

- Care instructions compliant with the Care Labeling Rule: This is the most complicated and difficult decision by Product team as typical scenario the instructions are based on material composition , embellishment on finished product and the kind of finishes. As a matter of fact, irrespective of the wash care instructions , every customer usually tends to do his owner regular domestic wash with available resources. Impact on Customer complaint will always contradict to the wash care label instructions.

- Disclaimer Tag: Any product which end to loose properties due to multiple factors must have a disclaimer tag. Consumer awareness is always key to Brand Quality.

Symmetry Fabric Patterns that Match Up

What makes a stripe or a Plaid garment look unique??

It is the symmetry that always catches the eye. Take a look at the seams of any garment you're considering to see how much effort has gone into matching up patterns. For bold patterns, like plaids and stripes, a poorly-matched seam looks untidy. Assume any sloppy match-up is a sign that little care went into the construction of the garment.

Finished Seams

Look at the seams of any outfit you're thinking of buying to make sure they lay flat and are free of puckers and other irregularities. Then, flip the piece inside out, and look at how the seams were finished. Unfinished edges are a sign of poor quality. Serged edges connote quality, but French seams, flat-felled seams, and bound seams are the true mark of quality.

Product Safety: The most important factor that I will emphasize is safety.

Drawstrings, Functional cords, Decorative cords,Small Parts , Sharp points ,Torque and Tension of small parts, Needle control Policy ,Metal Contamination Prevention

Did we define standards for safety aspects of product from Design to Manufacturing?

“Quality is what everyone wants in their clothing. If only it was easy to define what quality clothing is these days. Quality might appear to boil down to construction and cloth. But which cloth? Does it matter where a garment is made, or by whom? And are these really factors worth paying more for?”

Note: Above standards mentioned are illustrations of defining standards. These are not specific to any Brands.

RELATED TOPICS:#Apparel,Ajay Ravuri

Leave a comment

Our email address will not be published. Required fields are marked *

6 Comments

TiAzoxlJan 06, 2024 at 13:04 pm

levitra 20 mg precio farmacia This is a sensible approach to patients without a contraindication to steroid

John M. Bridges Dec 28, 2023 at 13:05 pm

Anindya, your blog opened my eyes to the importance of quality standards in apparel product development process. It's amazing how defining standards for things like puckering and color shading can make such a difference. Definitely learned something new!

Narayana gowdaNov 16, 2020 at 09:31 am

Great Article and very well explained Ajay, A good quality should come means every trims and manufacturing vendors and factory should be very important.If we will do together then will get good quality....

Umesh KamaladinniNov 14, 2020 at 17:42 pm

Good article Ajay, if we arrest major defects of raw material at initial stage, definitely there is a good output..

Manoj Kumar M.RNov 14, 2020 at 12:34 pm

Sir, it is a very good article well explained on the key points & Standards to be focused on for Quality. Yes Fabric, trim and construction techniques teams must work together to create a professional-looking garment. Great learning ???

YoganarasimhakyNov 14, 2020 at 10:42 am

Hi Ajay, Well explained about raw materials, raw material quality is very important role of every product.